Assembly

Contents

This is the video clip for the pre-assembled leg kit, please refer to the below sections for more detailed steps.

Please also refer to Mini Pupper Fusion 360 CAD model: https://a360.co/3wFLSlT

0. Update change points after April 15 2022

Updated the body and hip parts from 3D printed to mold.

Re-designed and unified the original four hip parts into one for mold, for the detailed info, please refer to the mechanical design section.

If you get your Mini Pupper kit after April 15 2022, it will be easier to assemble.

If you have 3D printer and still hope to use the previous 3D printed design, that’s OK.

1. Write the pre-built image into microSD

Tools

In addition to the tools included in the kit, the following items are required for assembly.

USB keyboard

USB mouse

PC

microSD card reader

HDMI Display

micro HDMI cable

USB charger

Step 1.1 Charging the battery

The battery is charged via USB, see picture for USB socket, and can also be charged while attached to the Mini Pupper body.

※ LED light: Green means there is enough power, and Red means you need to charge it.

※ We recommend 5V/1A adapter, if you use 5V/2A adapter, the battery IC will change it to 1A. It needs about 1 hour to charge 80% and the light will become green, and an additional 1 hour to 100%, anyway, you can use it when the light becomes green.

Step 1.2 Download the image

You can download latest image file via the below folder.

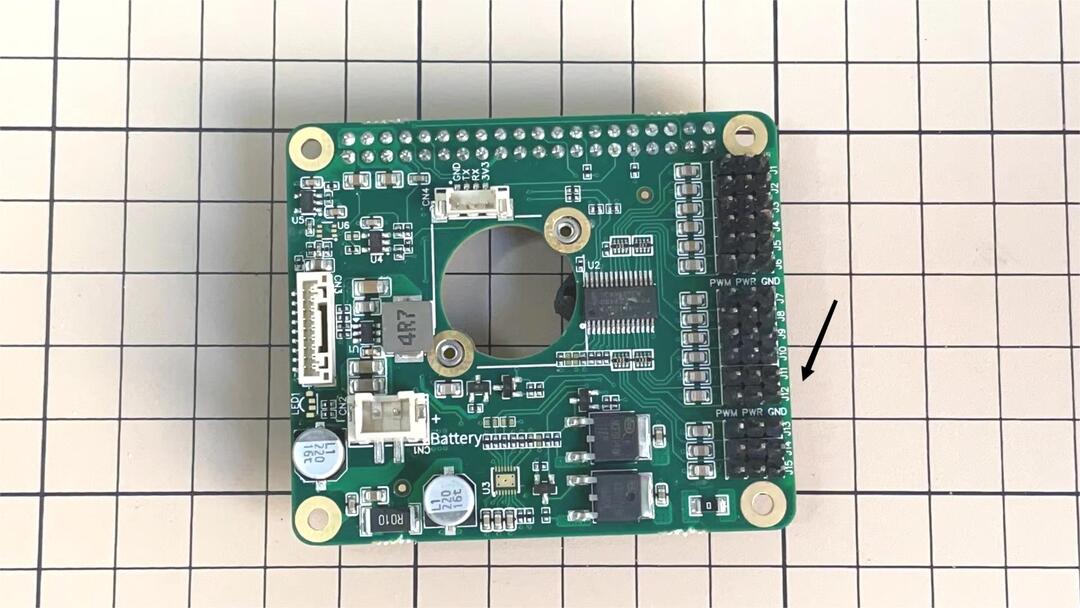

The below picture is the custom carry board.

※ “xxx_MiniPupper_Controller_Ubuntu_22.04.img” means the image is for Ubuntu 22.04 version.

※ “xxx.MiniPupper_ROS&OpenCV_Ubuntu20.04.03.img” is the image file for the Ubuntu + ROS + OpenCV version for SLAM & Navigation & AI.

Step 1.3 Write the image into microSD card

Insert the microSD card into your PC’s SD card reader and write the image. We recommend the image creation tool balenaEtcher or Win32DiskImager as it is easy and reliable. Please refer to the official manual and below link. It may take a while to complete.

※ Reference Link: Download Etcher – Flash OS images to USB drives & SD cards

Remove the SD card from the PC and insert it into the Raspberry pi.

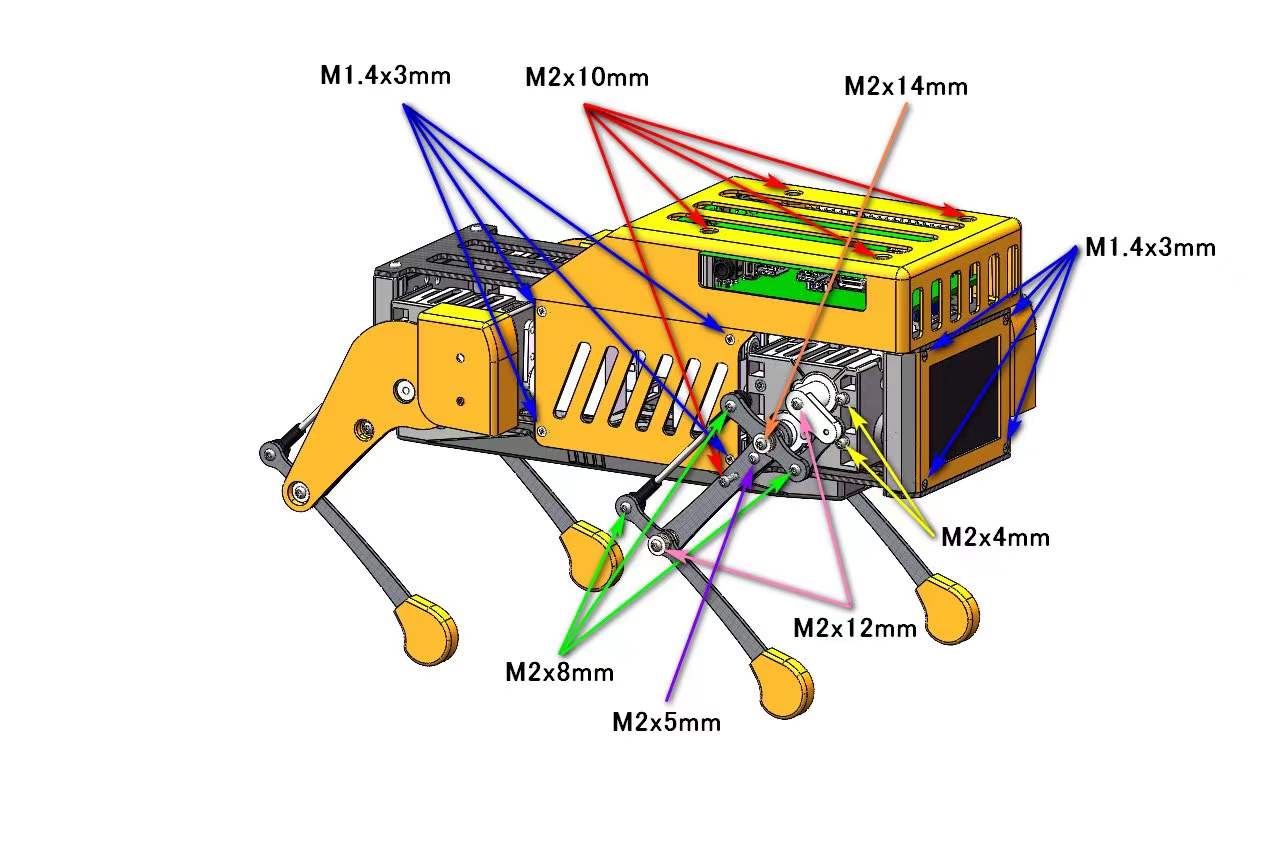

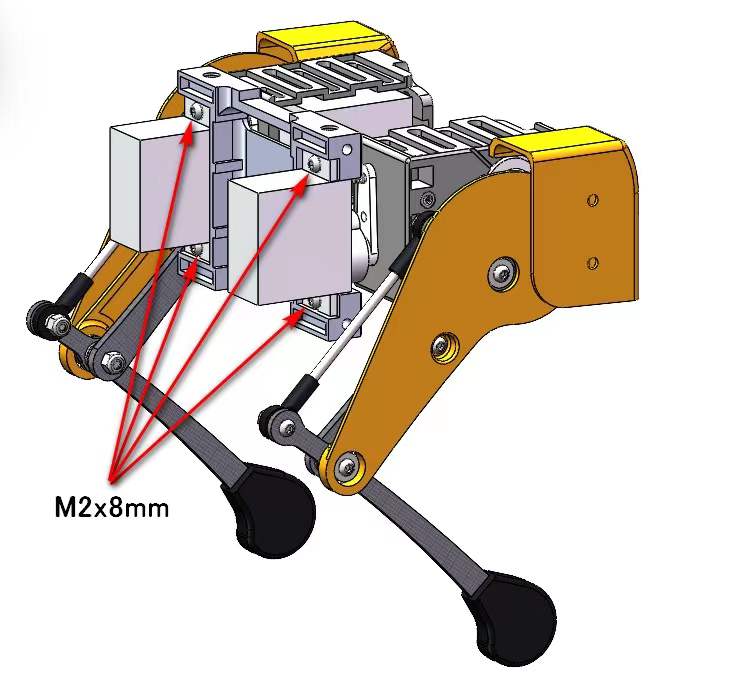

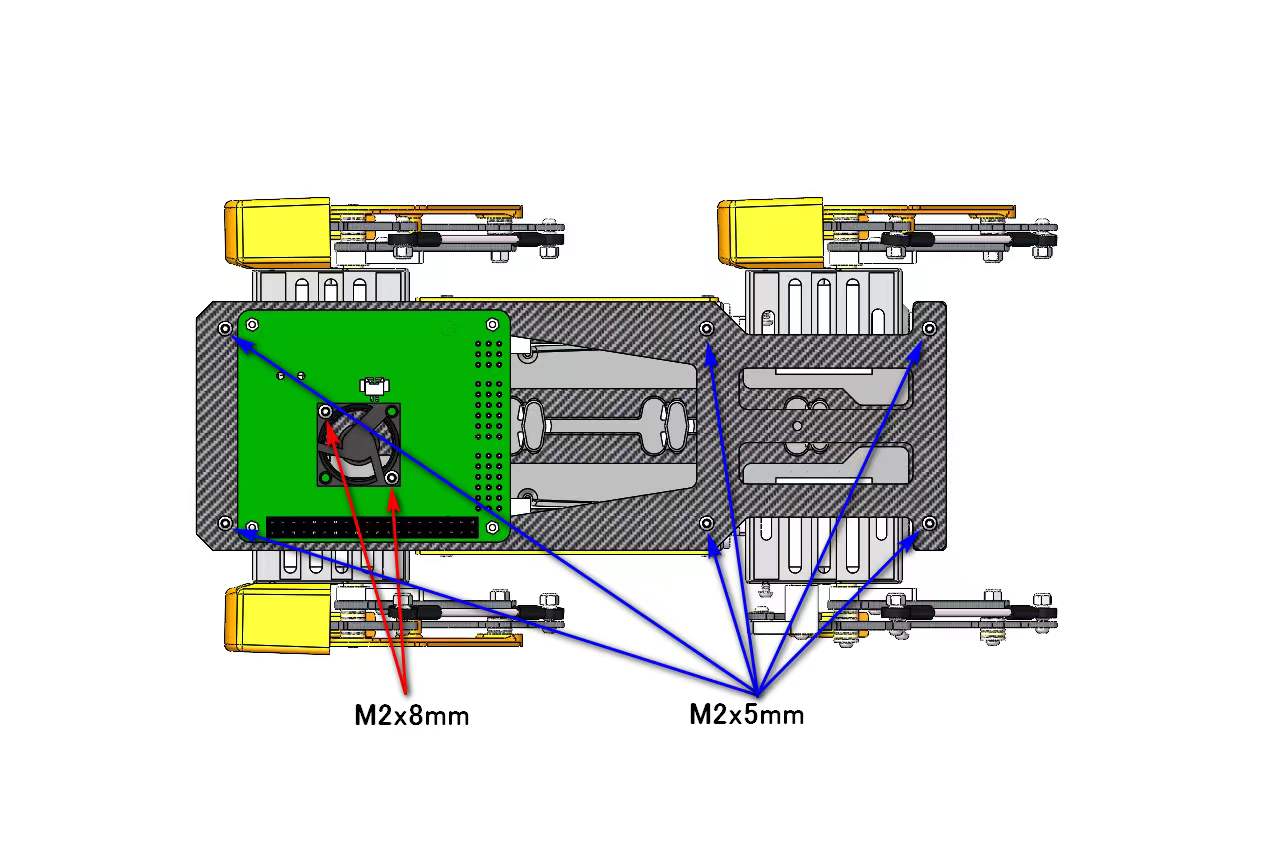

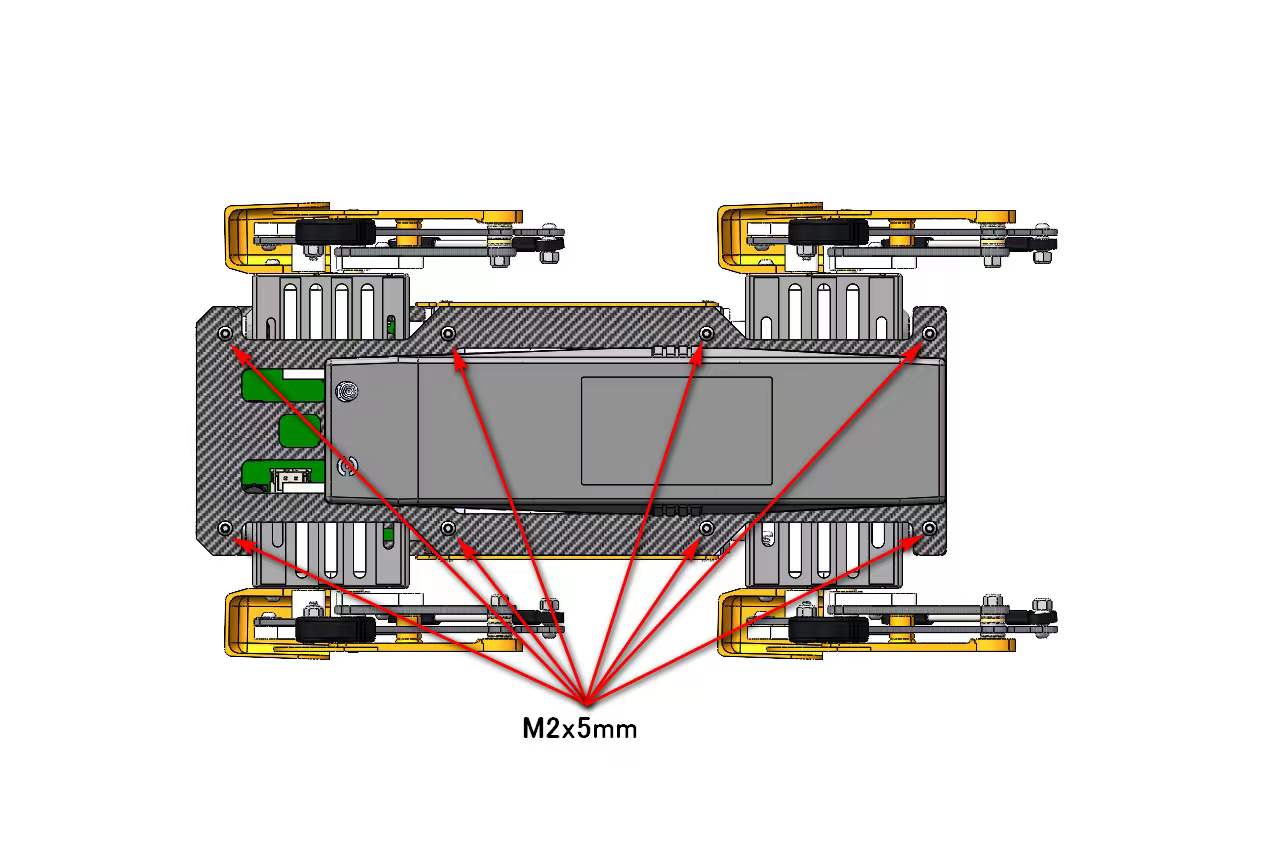

2. Position of the screws

The pictures show the position of the screws briefly.

(The up pictures are before April 15 2022 version, the below pictures are after April 15 2022 version)

(The up pictures are before April 15 2022 version, the below pictures are after April 15 2022 version)

3. Legs Assembly

Please refer to the below video clip.

Tools

In addition to the tools included in the kit, the following items are required for assembly.

Loctite

※ We don’t recommand new users to use the Loctite at first, you can use it after you have much background.

※ Loctite prevents the nut from loosening, but it is not essential, as it can be tightened only when looseness is noticed.

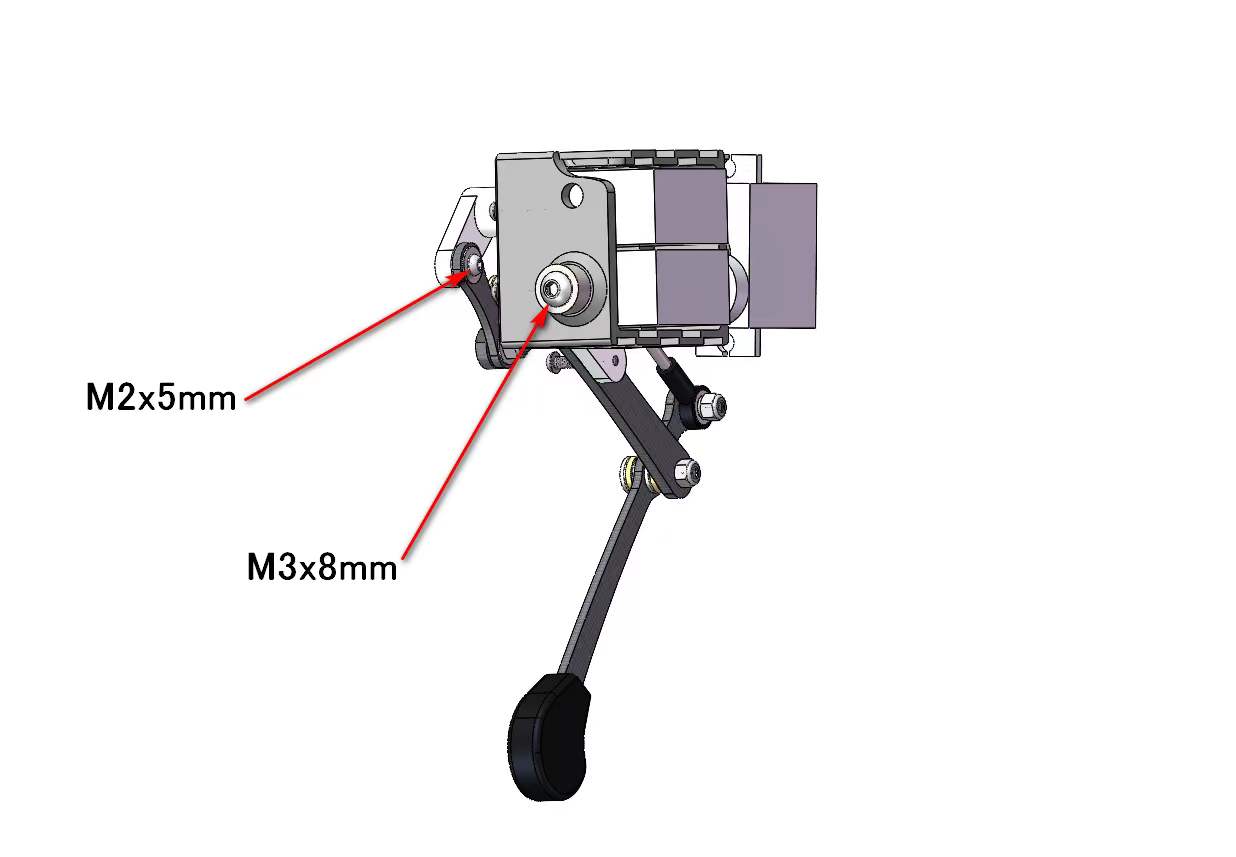

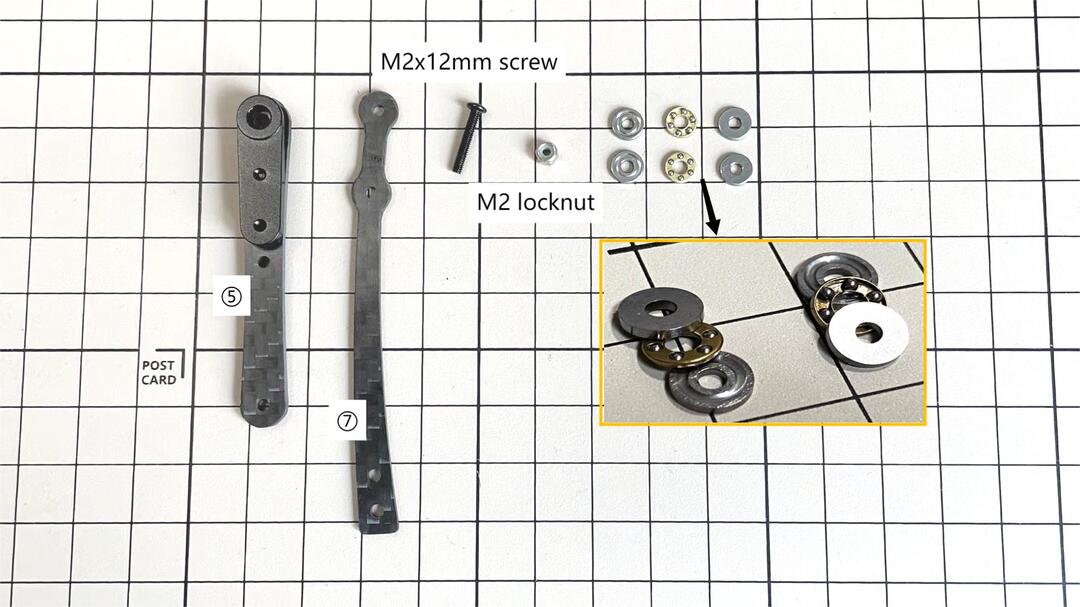

Bolt to use

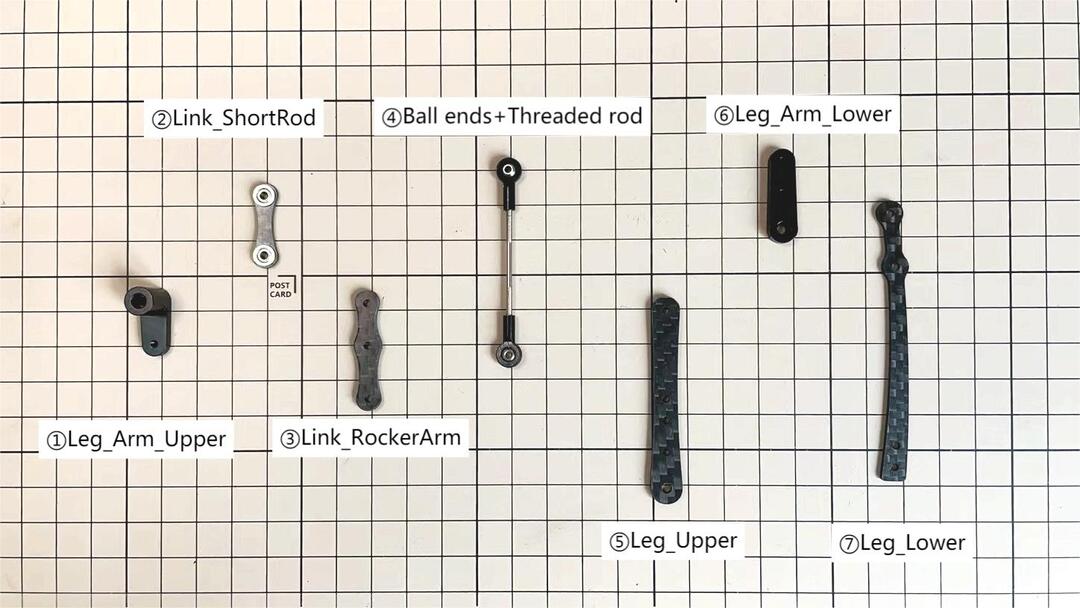

M2x5mm 2x4=8 ①+②, ⑤+⑥

M2x8mm 3x4=12 ②+③, ④+⑦, ③+④

M2x12mm 1x4=4 ⑤+⑦

M2x14mm 1x4=4 ③+⑤

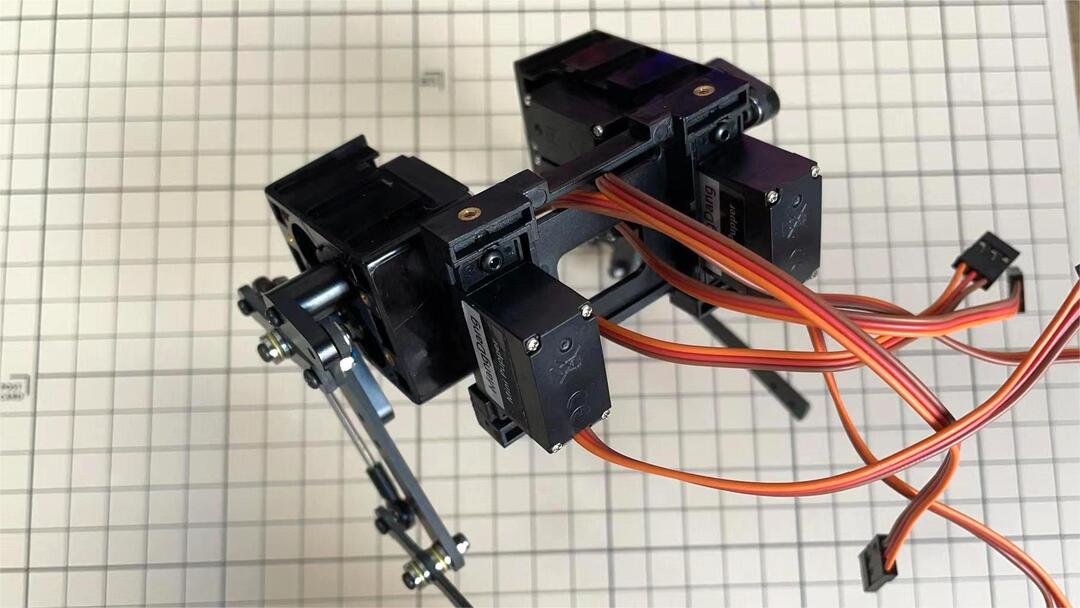

Step 3.1 Single leg

Assemble the four legs. The front and back of the right side are the same, and so are the front and back of the left side. Show you how to assemble the right side.

Video Instructions, please refer to the link https://youtu.be/Ut7UnS3CTZs

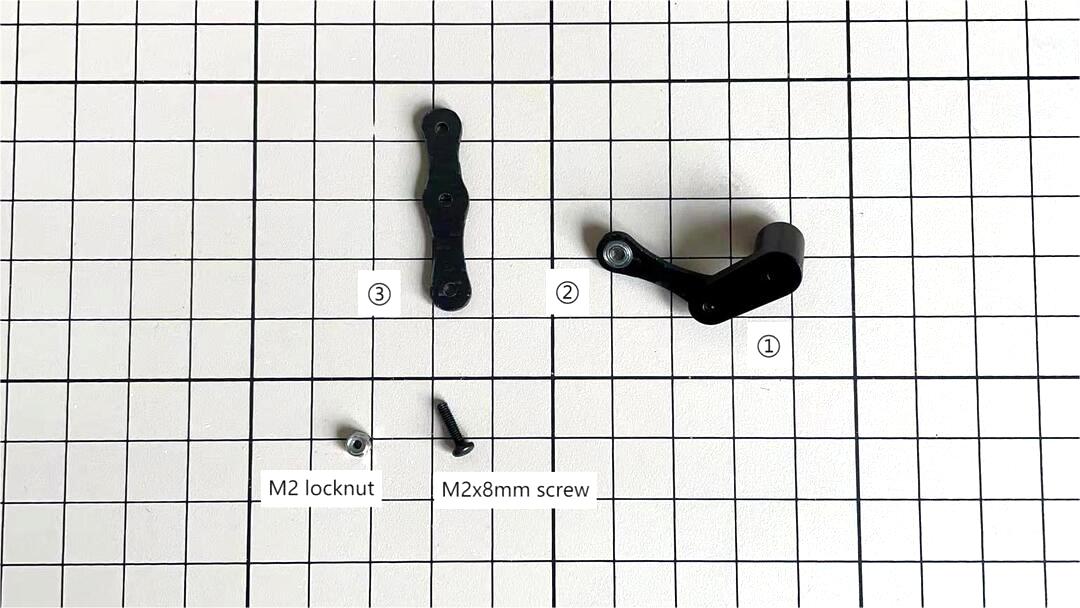

The parts are numbered as follows to explain.

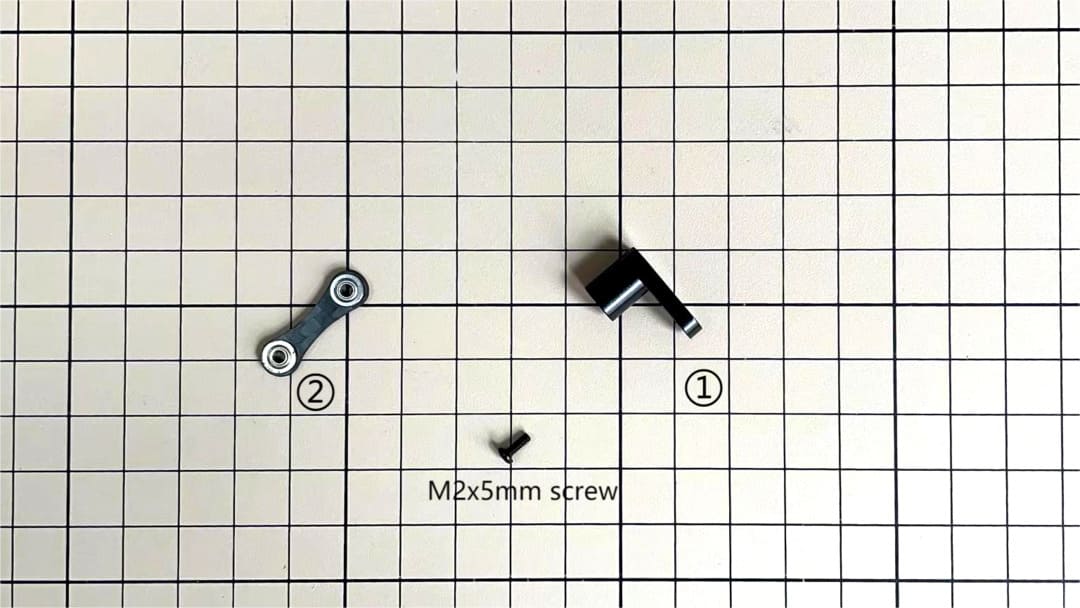

Assemble ① and ②

Use one M2x5mm screw.The screw is inserted from the bottom of ② upwards and tightened by inserting them into the screw holes in ①. Be careful about the sides of ②.

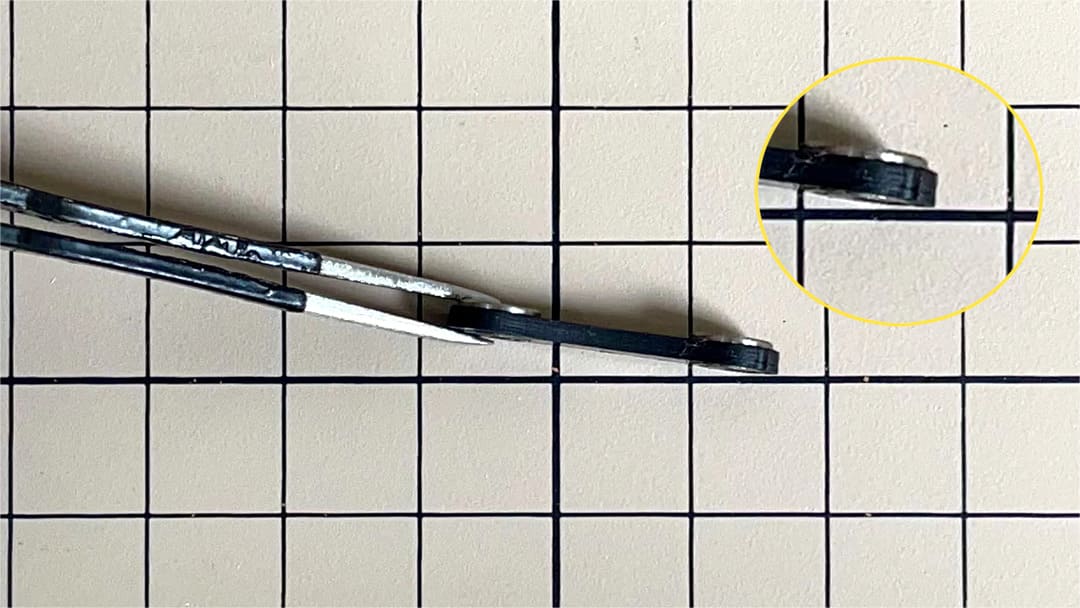

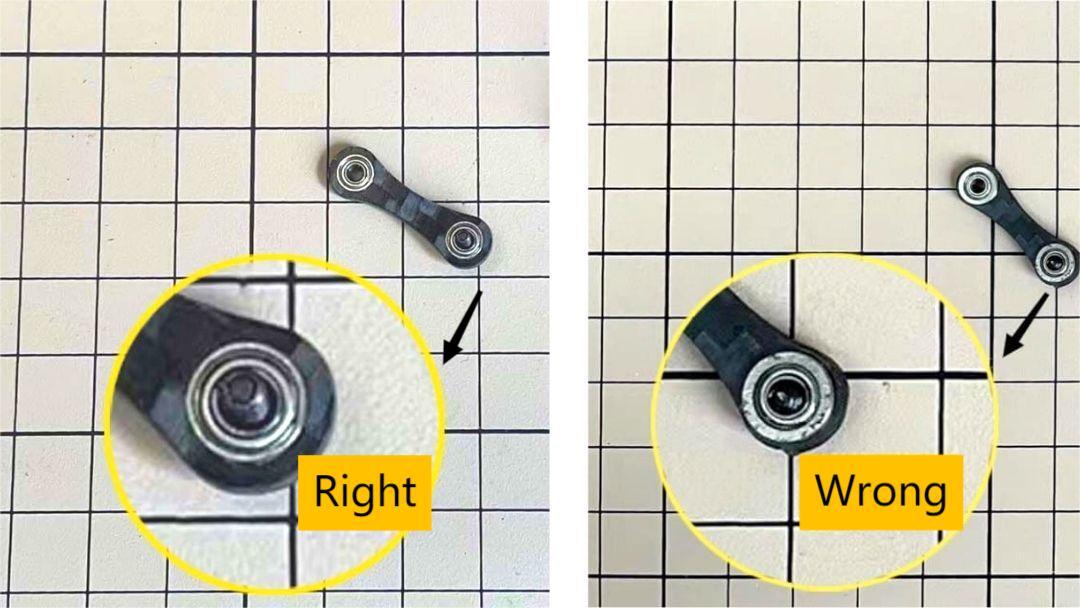

The two ballbearings in ② should be inserted all the way in and the end should be slightly visible as shown in the picture below. Tap the ball bearing and press it in without gaps.

Assemble ② and ③

Use an M2x8mm screw and an M2 locknut. Insert the screw from the bottom to the top of ③, pass through ② and tighten with the nut. It is important to pay attention to the orientation of ③. Look carefully at the position of the hole in the middle.

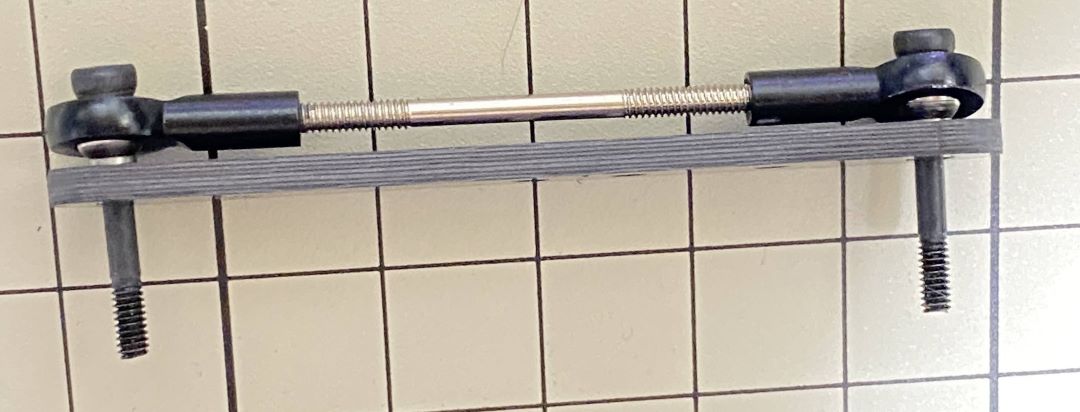

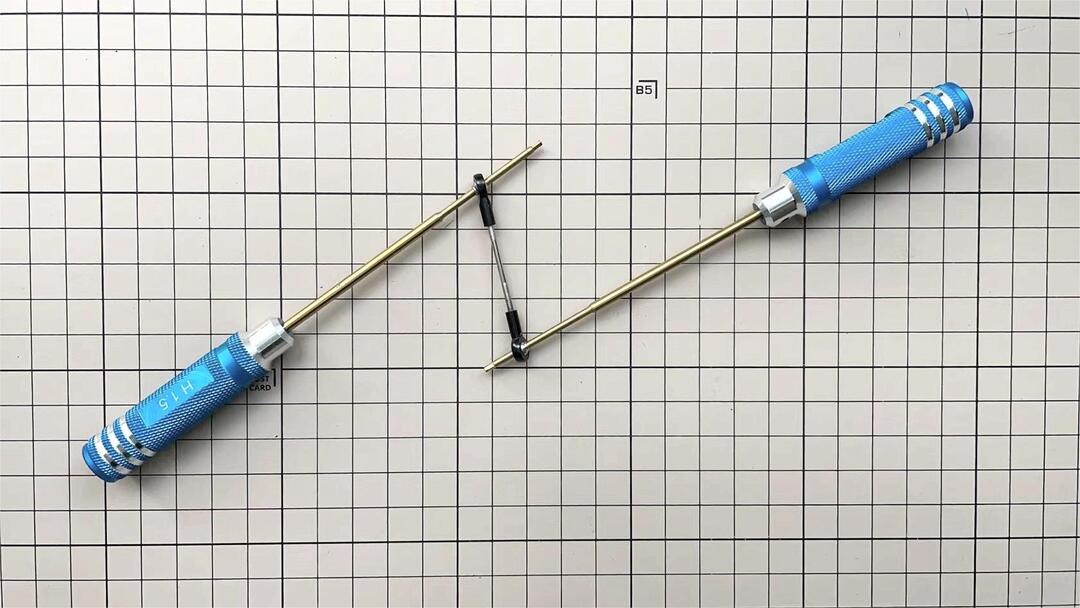

Adjustment of the length of ④

The length of ④ must match the length of ⑤. When adjusting the length, it is easier to use two long screws to make sure that the lengths match. Once the lengths have been adjusted, take apart all.

If it’s hard to twist, you can use two screwdrivers to assist.

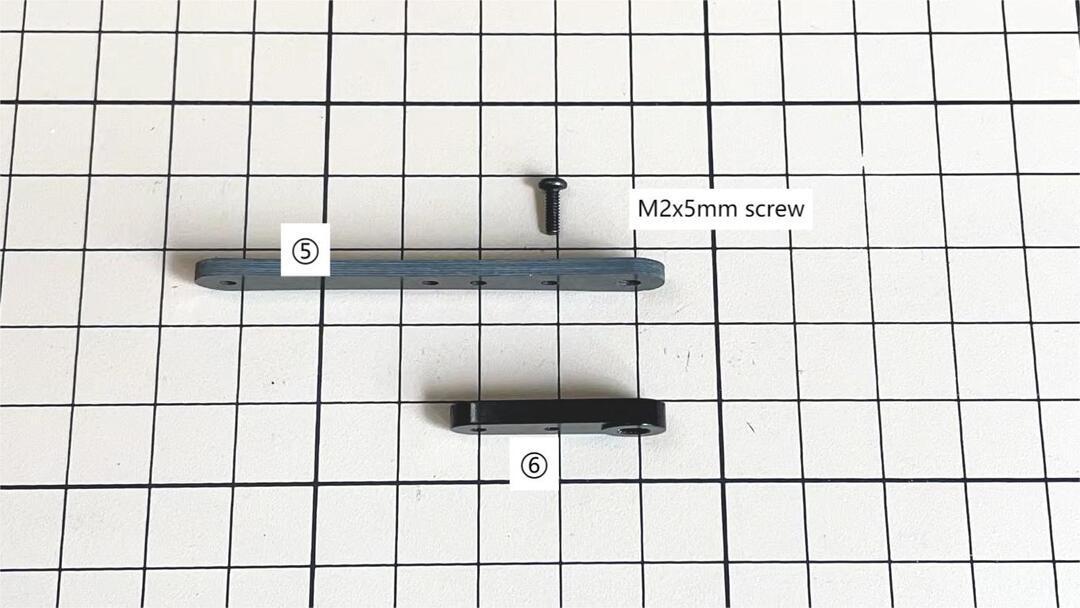

Assemble ⑤ and ⑥

Use one M2x5mm screw. Insert the screws into ⑤ first, insert them into the holes of ⑥, and tighten them. The large hole in ⑥ should be facing the surface.

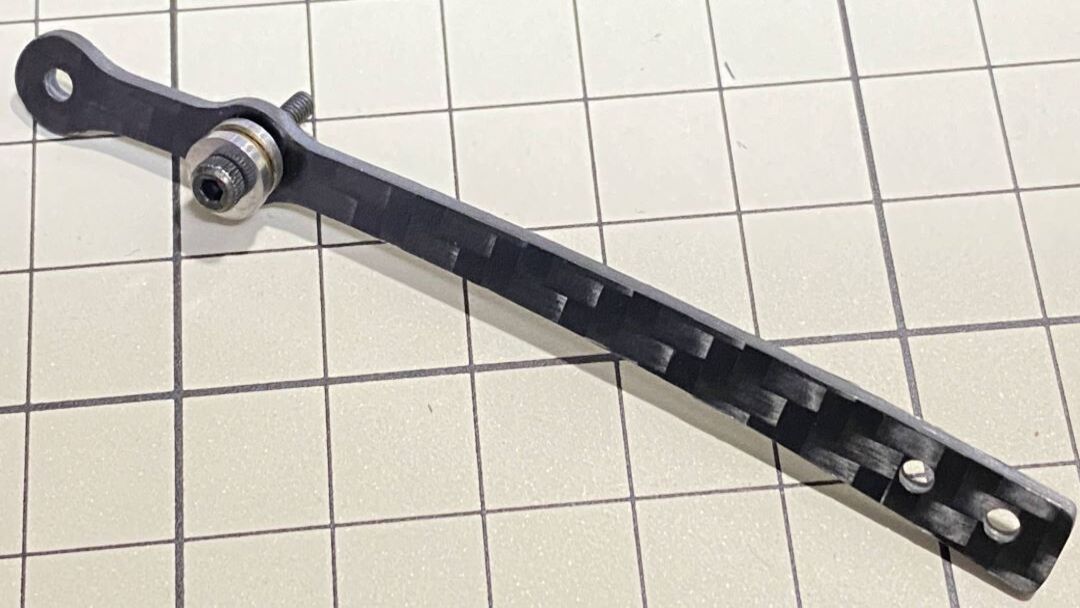

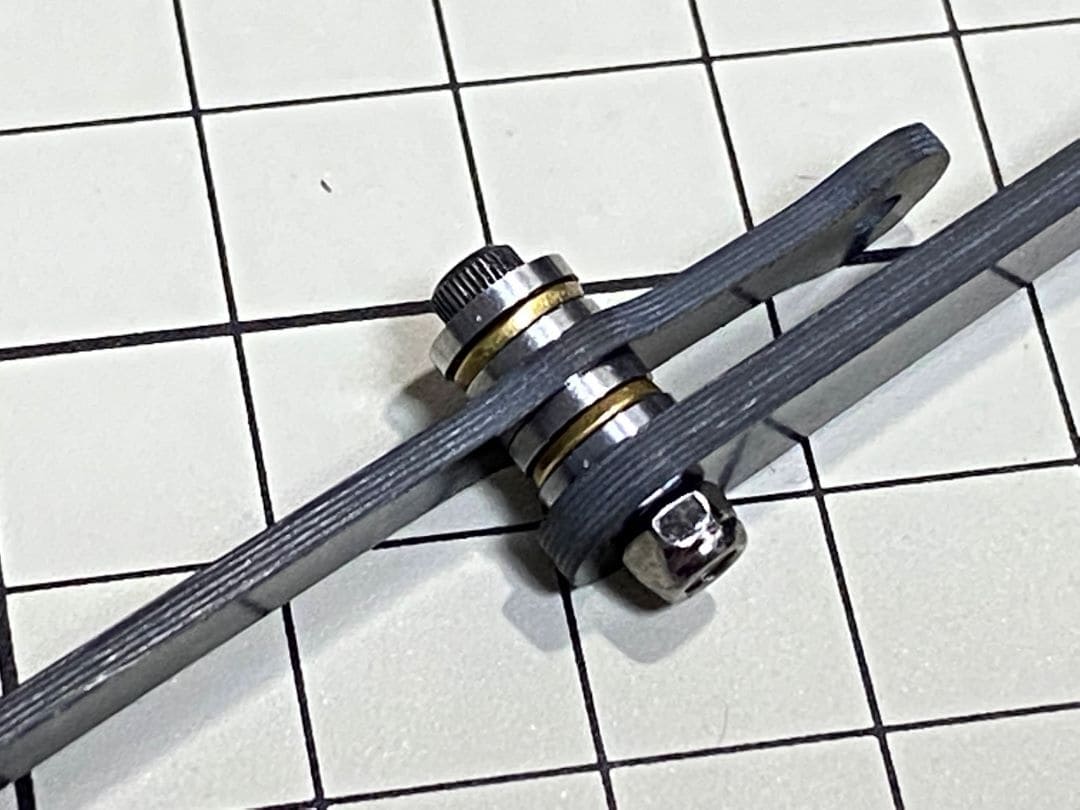

Assemble ⑤ and ⑦

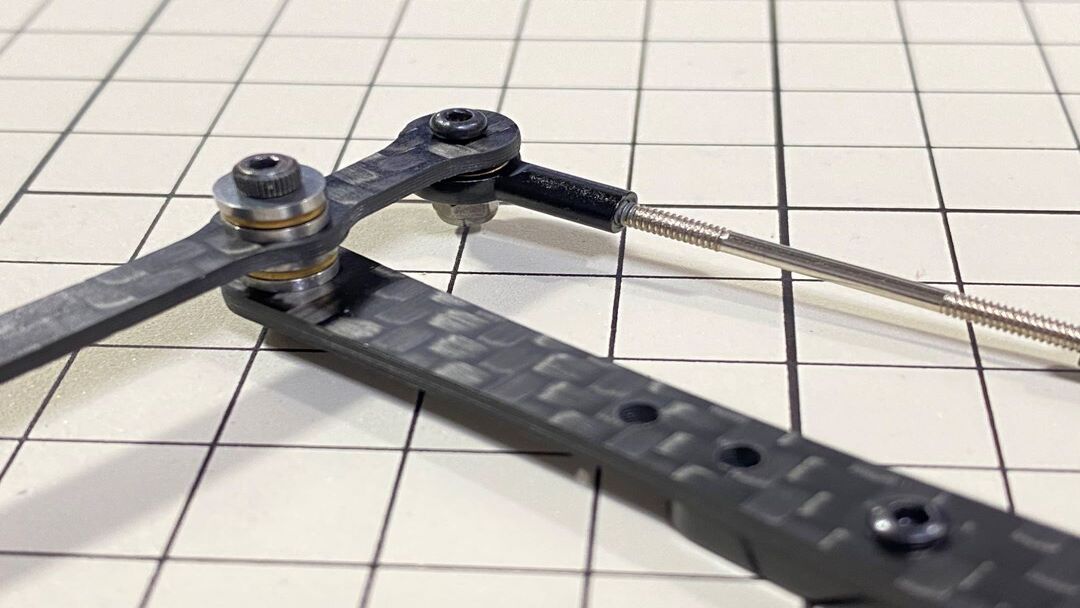

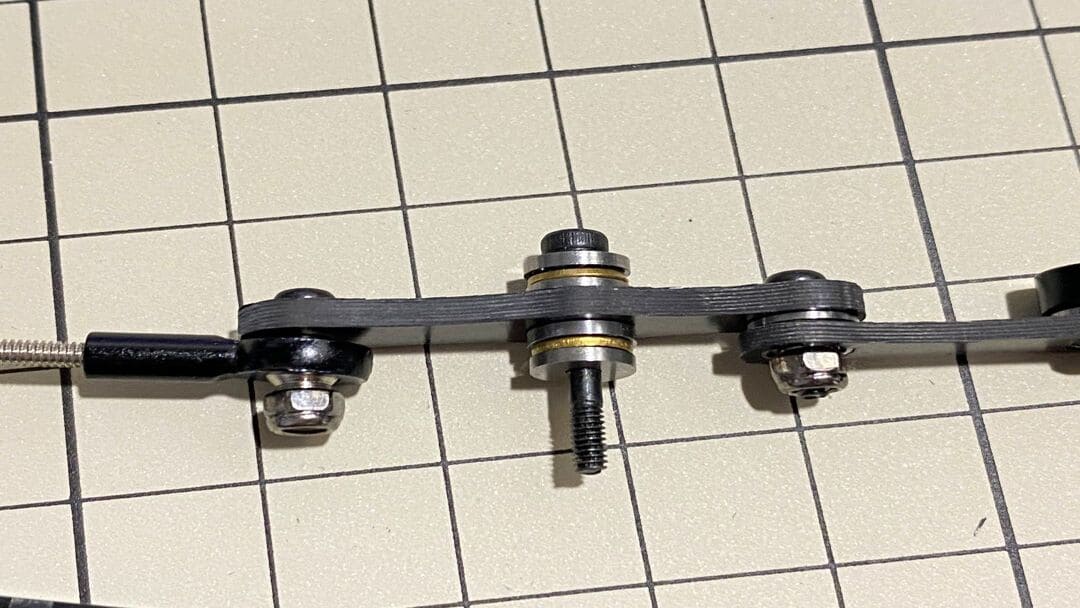

Use an M2x12mm screw, an M2 locknut and two sets of ball bearings. Each ball bearing is made up of three parts, the top and bottom parts with the grooved side facing inwards. Insert a screw into a set of ball bearing. Then insert the screw into the hole ⑦. Taking care to look at the warped side of ⑦ to make sure it is facing the right way. Now screw in the another set of ball bearing. Finally, insert screw into ⑤ and tighten it with the nut.

Assemble ④ and ⑦

Use an M2x8mm screw and an M2 nut. Insert the screw into ⑦ and put ④ through, then tighten it with the nut. The direction of the front and back of ④ can be either.

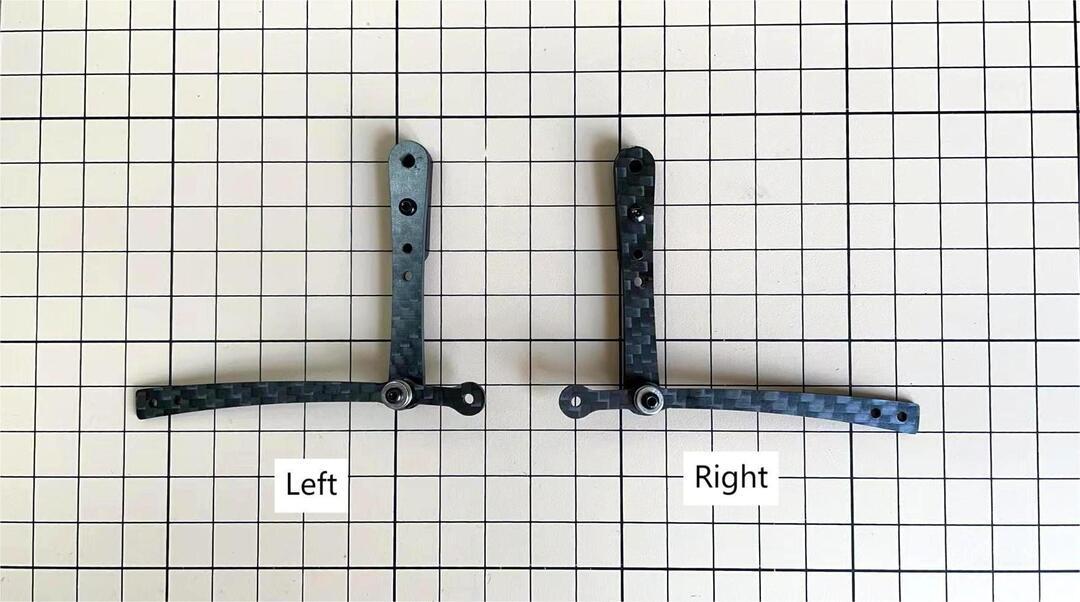

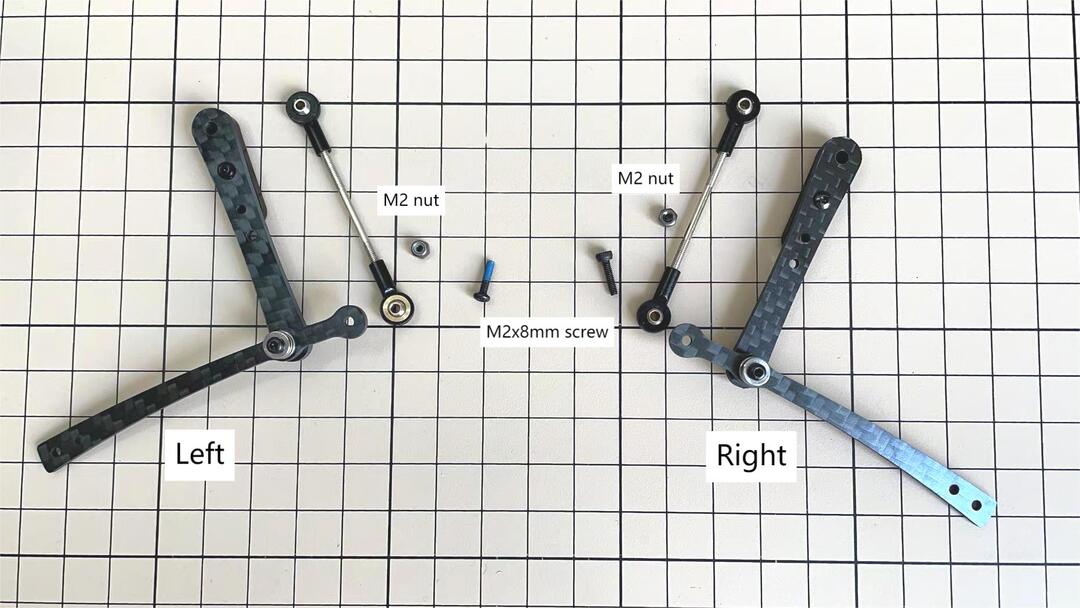

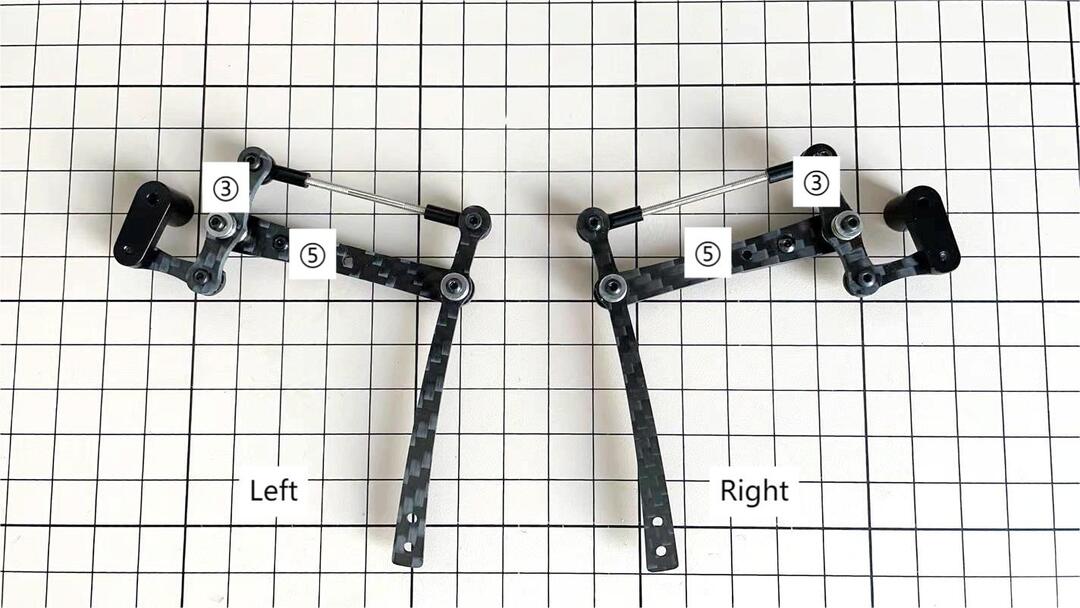

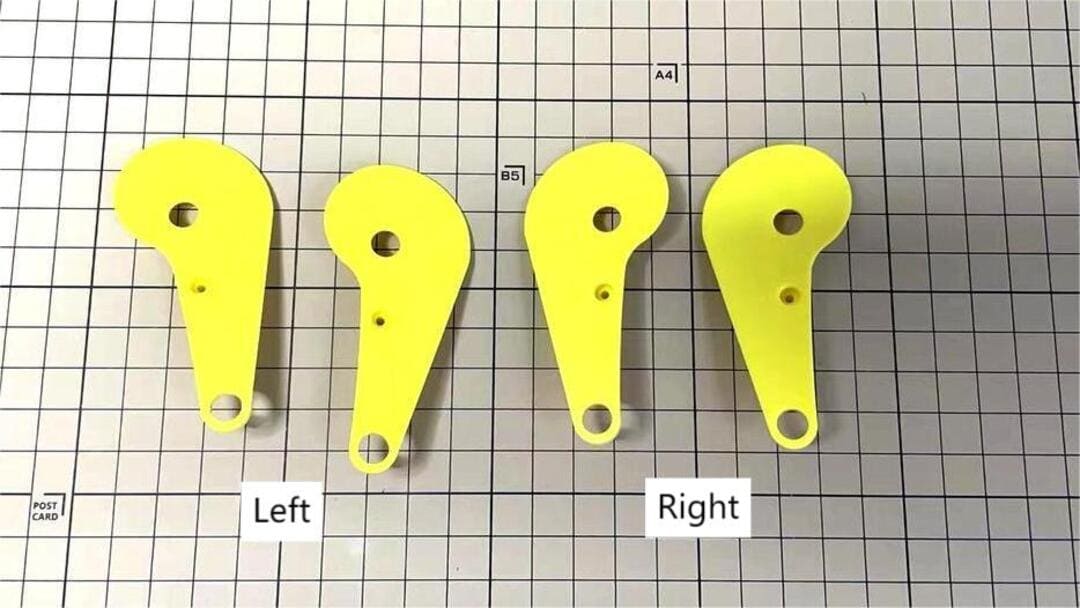

Left and right leg

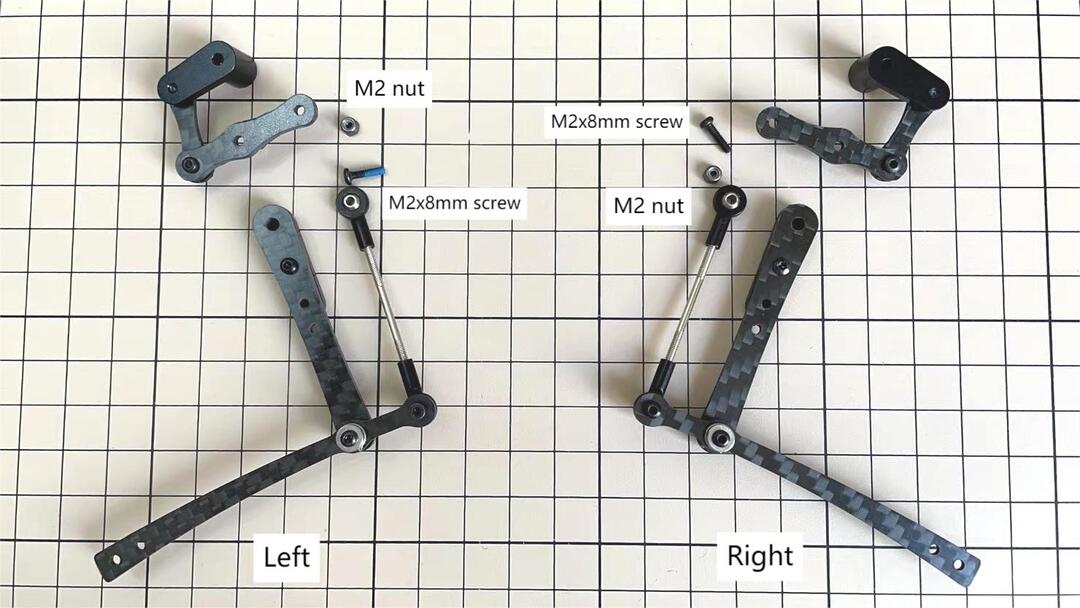

Assemble ③ and ④

Use an M2x8mm screw and an M2 nut. Insert the screw into ③ and put ④ through, then tighten it with the nut.

Left and right leg

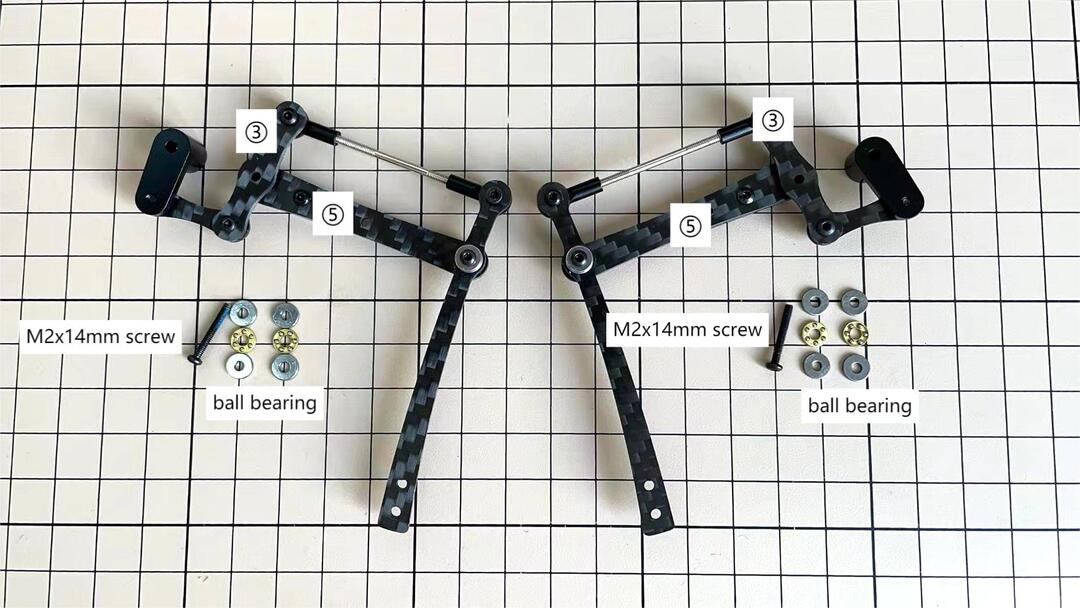

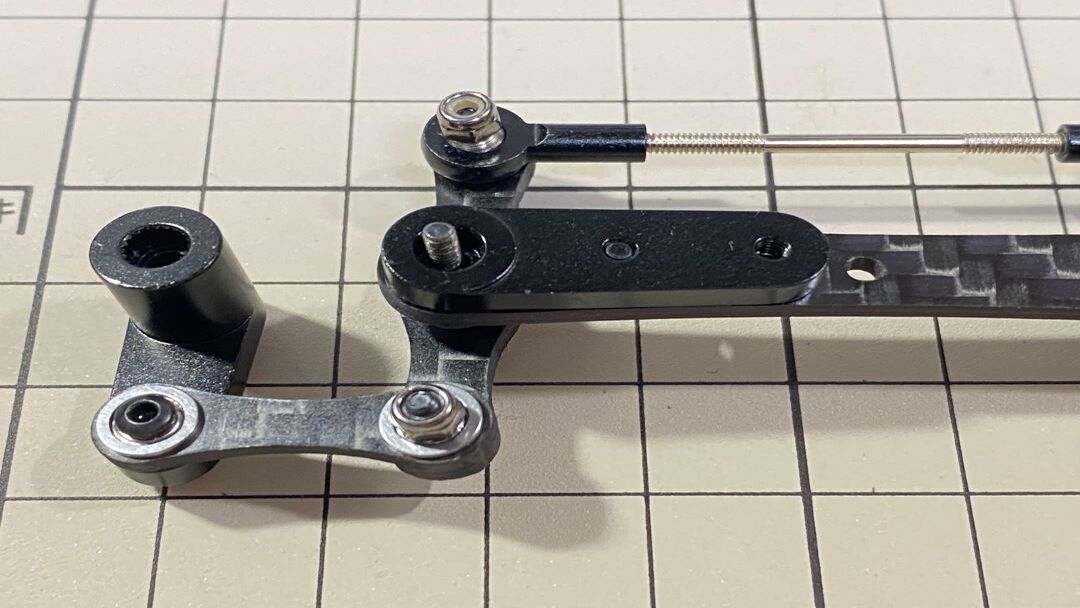

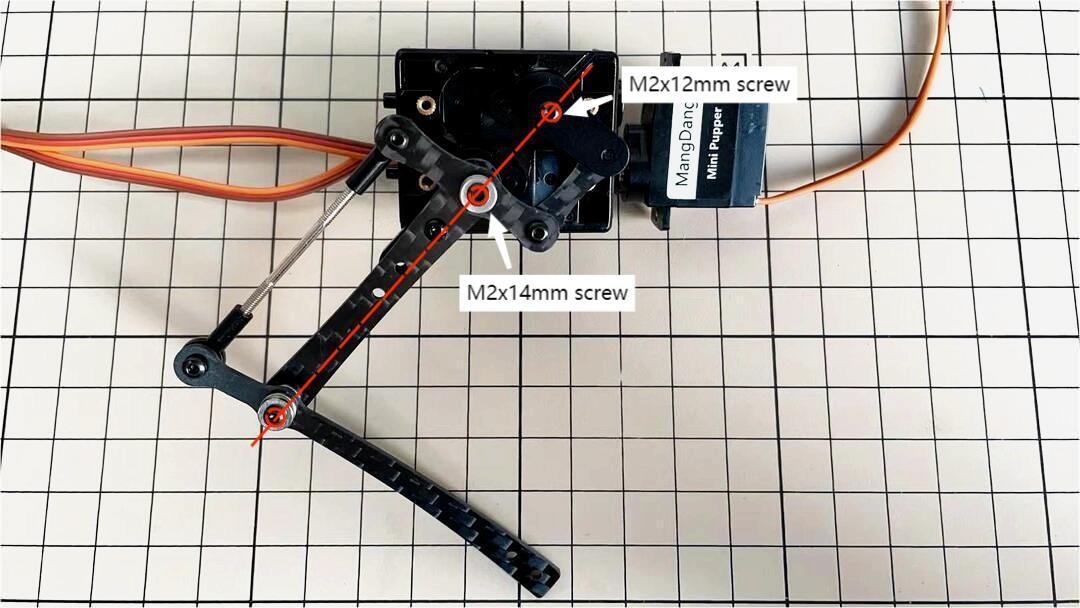

Assemble ③ and ⑤

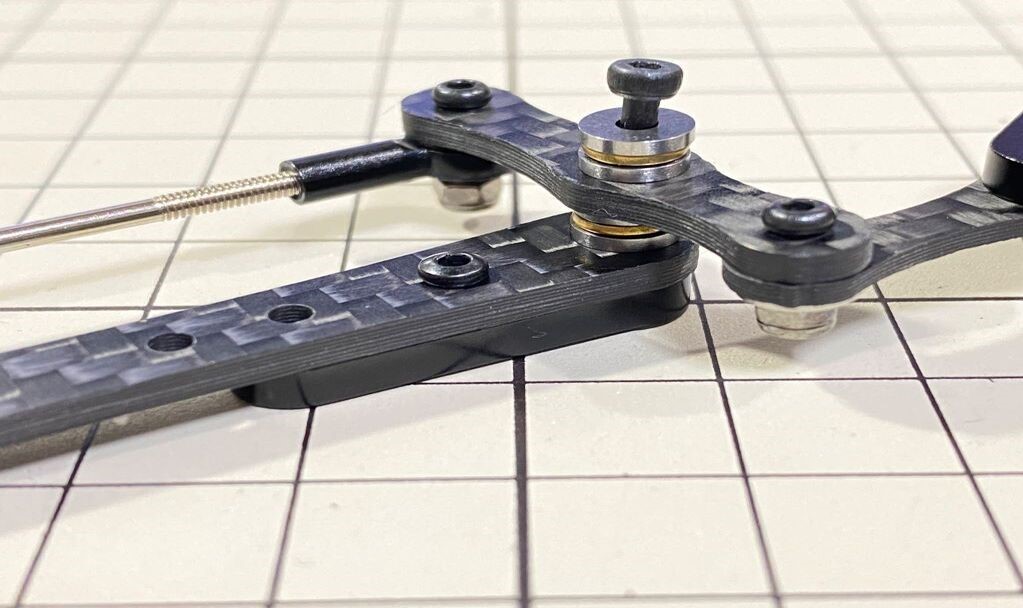

Use M2x14mm screws and two sets of ball bearings. Thread the screws through the bearings, ③, bearings, ⑤, in that order. The screws are not fixed, but you will tighten them when you mount the servo in the next step.

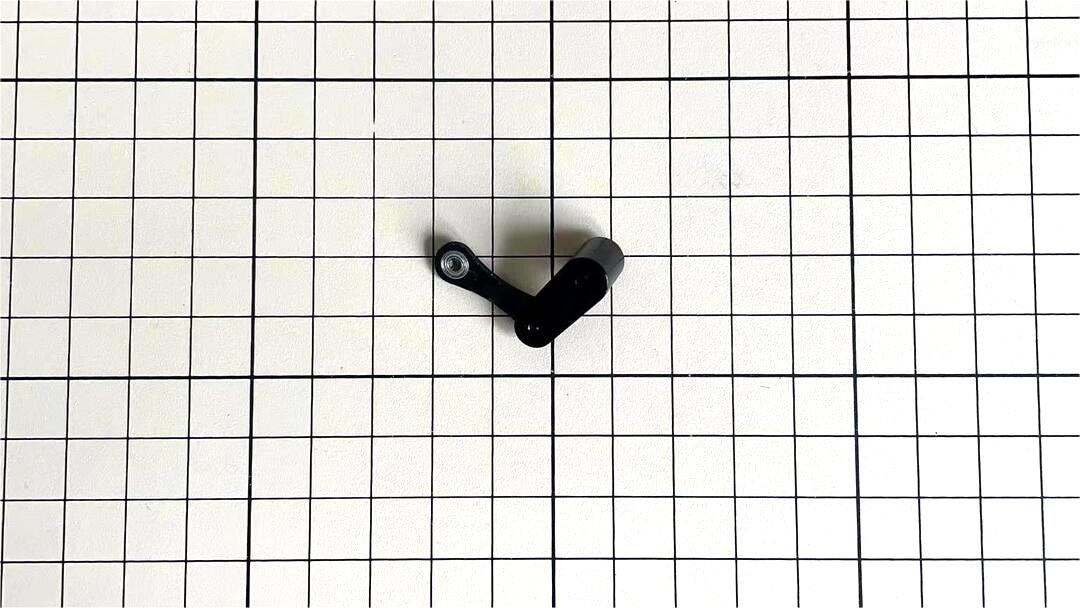

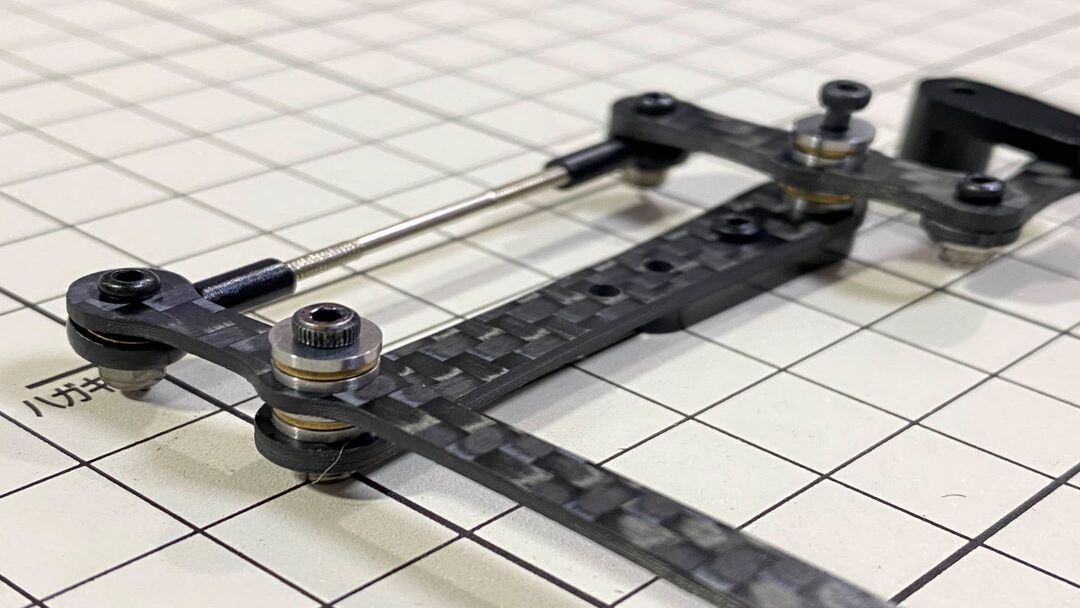

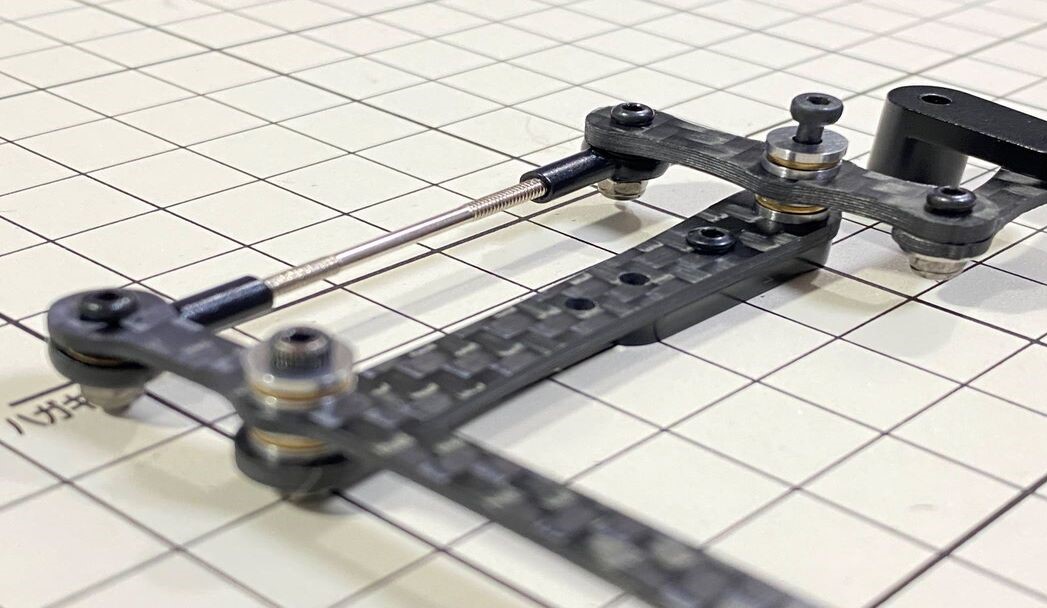

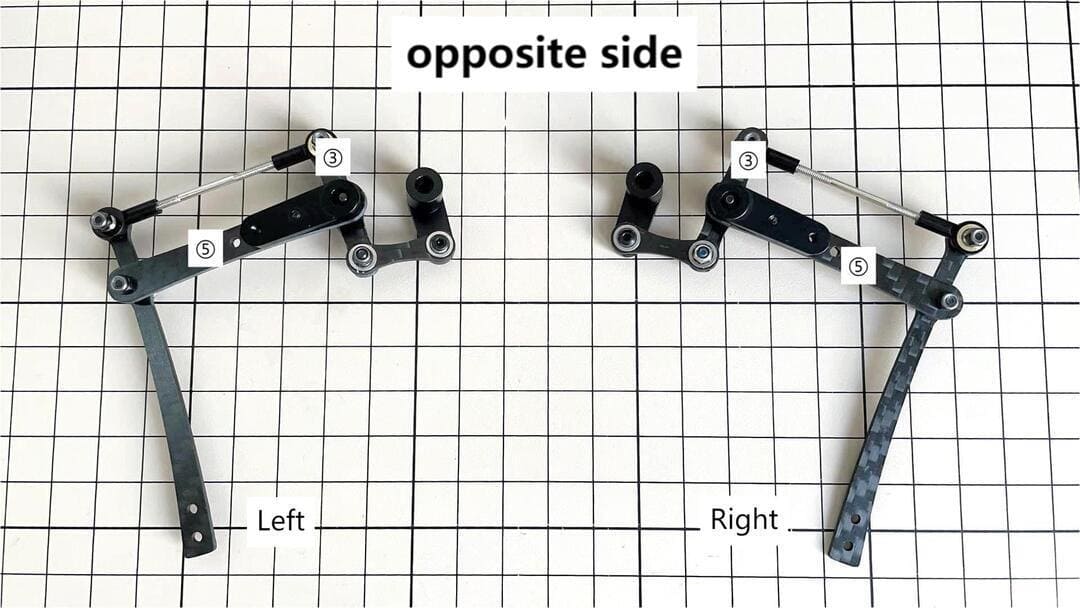

Completion of a right leg

Now we have one leg on the right side. Here are some pictures so you can see it from different angles. The left leg should be symmetrical with the right one.

opposite side

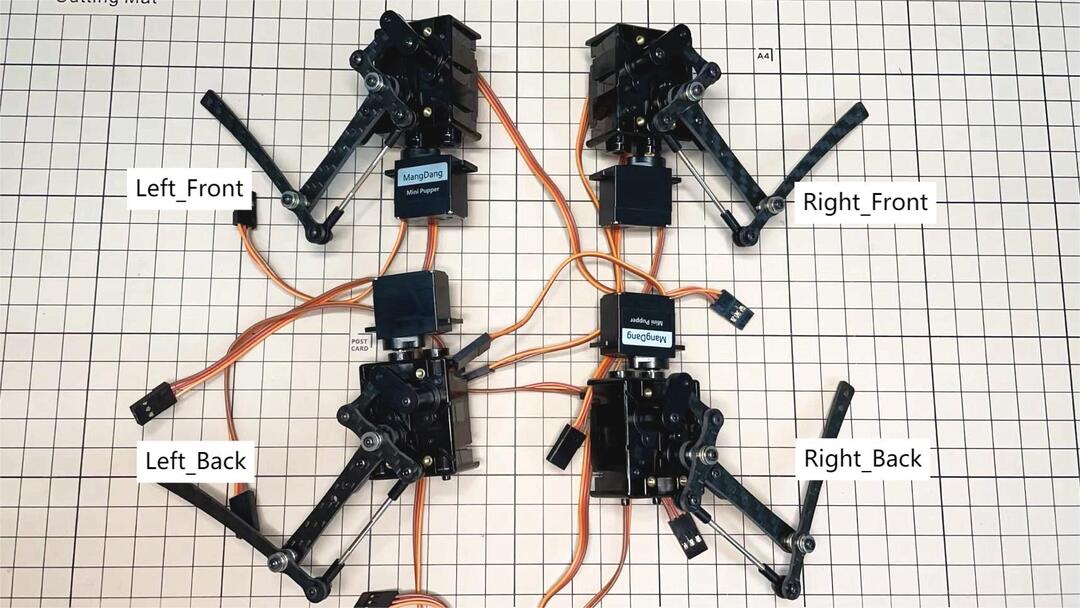

Step 3.2 Four legs

Step 3.3 Locktite

As the nut is on a moving joint, it will loosen quickly if tightened too tightly. They should be secured with Loctite. It is possible to dismantle the nut later, as it can be loosened by a strong force.

Some screws are also secured with glue as the below picture shows.

4. Hips Assembly

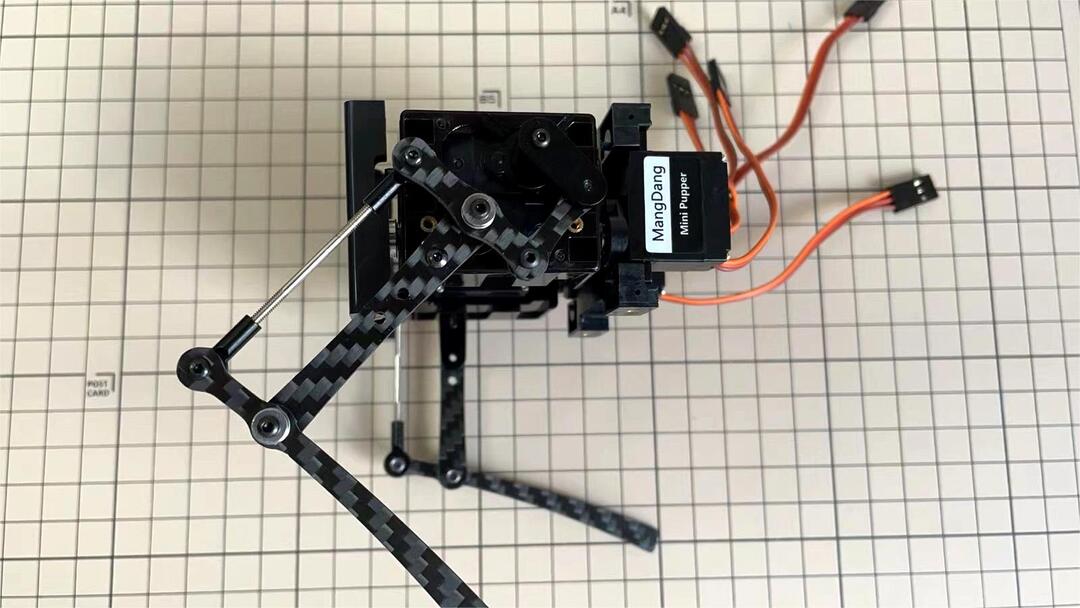

Step 4.1 Hip

Please refer to the below video clip.

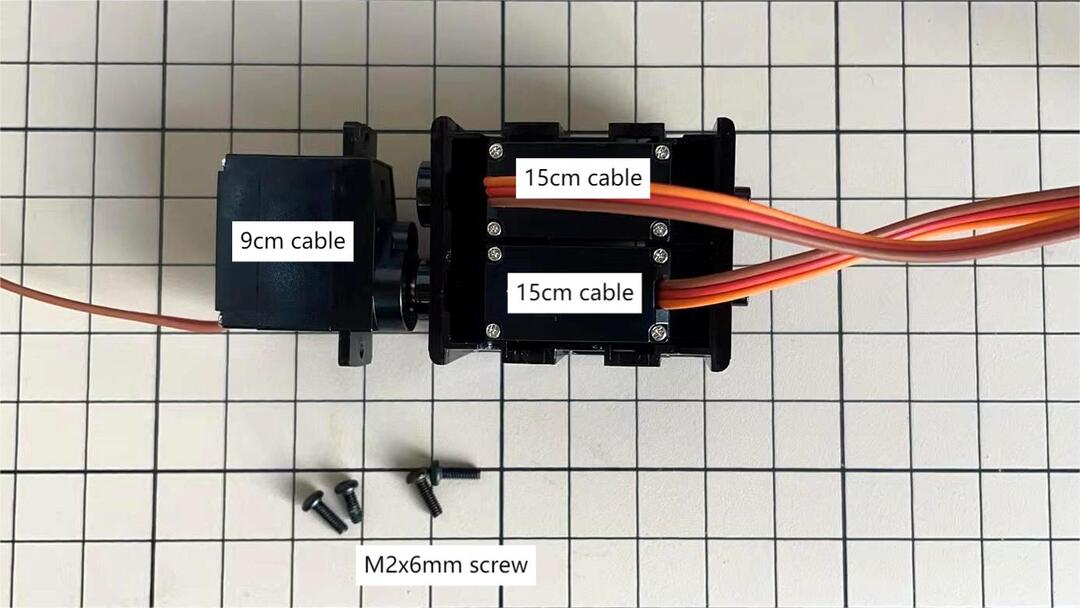

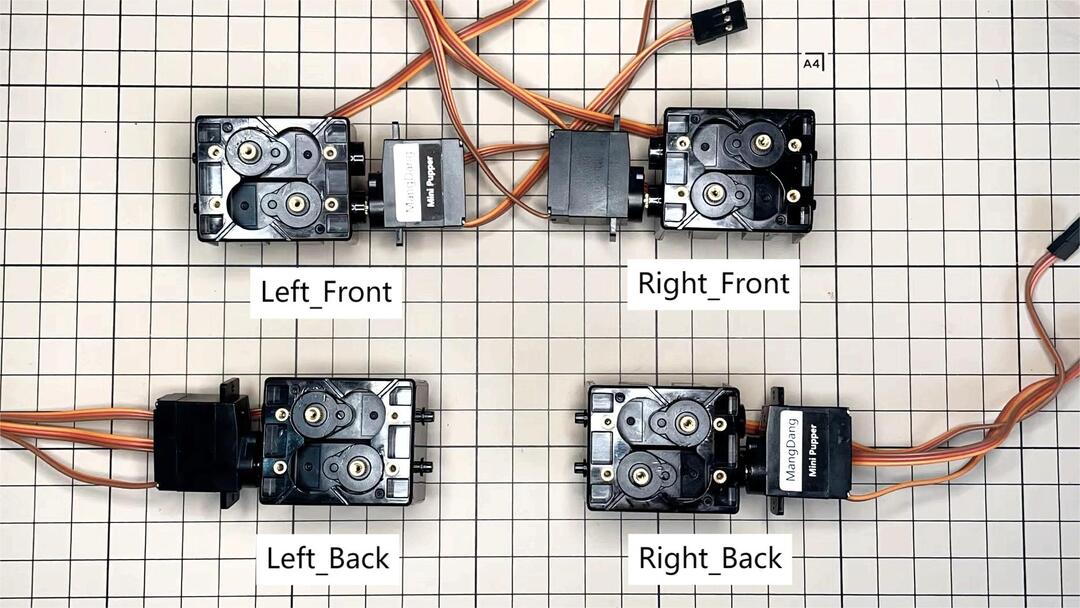

There are two kinds of servo cables, No.1,4,7,10 cables length is 9cm, other cables length is 15cm.

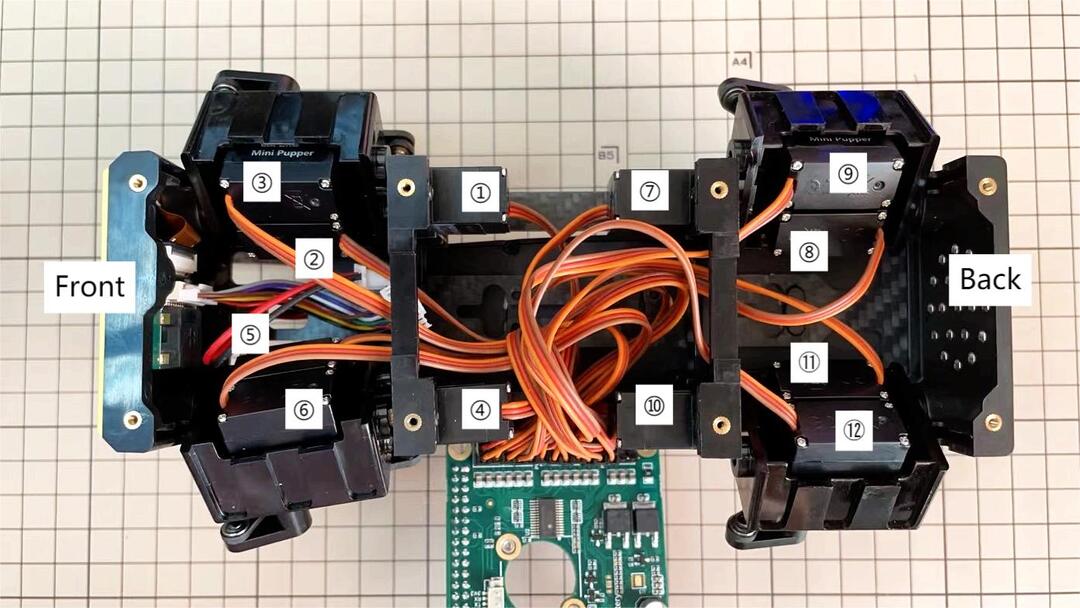

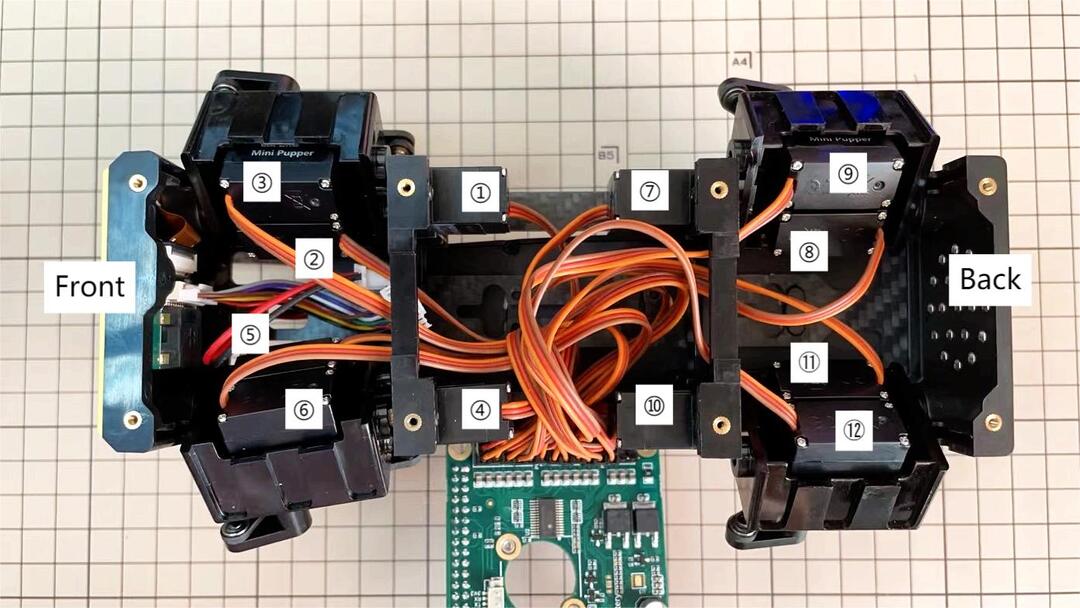

For the position of each servos, please refer to the below picture.

Here shows how to assemble the rear right hip.

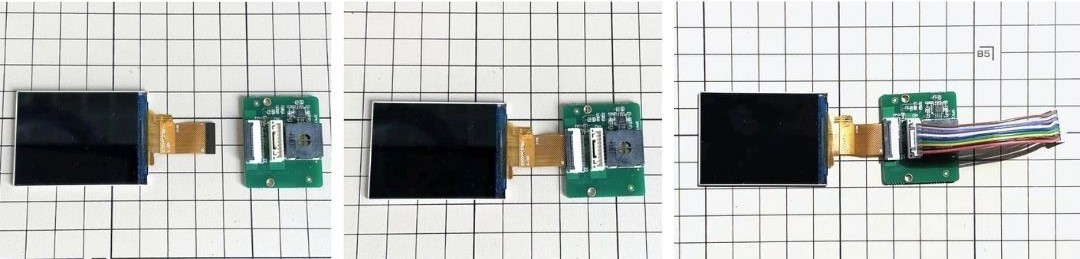

Confirm whether the servo shaft is at the right position. The middle position marker is added on the output shaft, the output shaft is at its middle position by fault as the left picture shows. The shaft position may be changed during assembly as the middle picture shows, if you find it, you can use the servo horn to move the output shaft to the right position, and then finally make the servo horn at the place as the right picture shows.

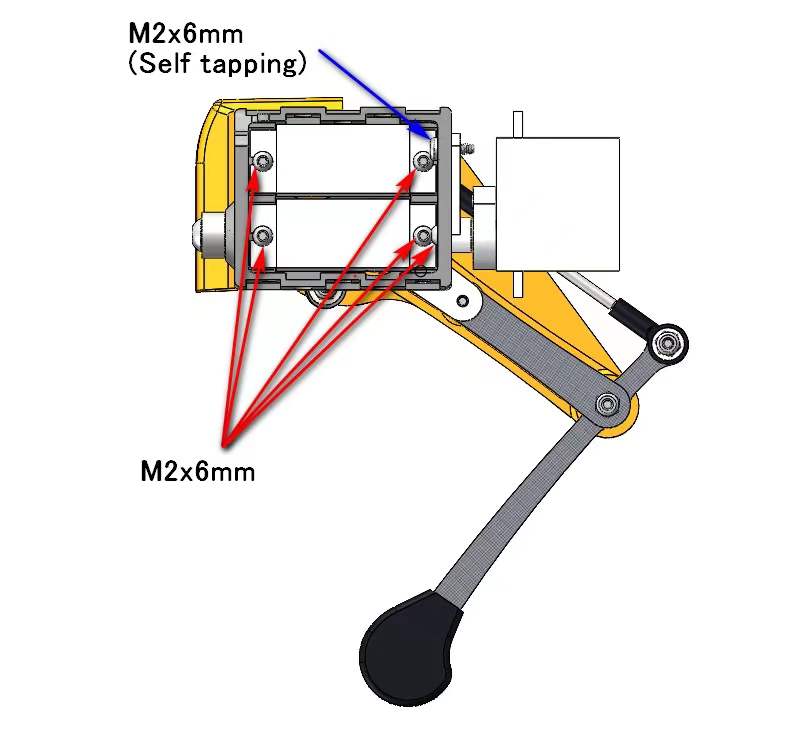

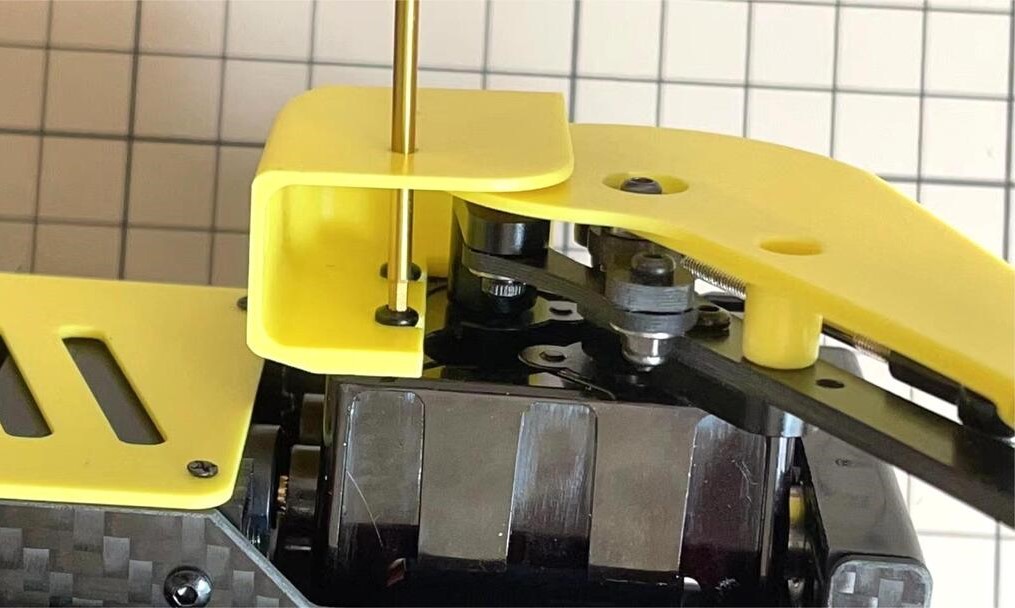

Connect the servo and hip part.

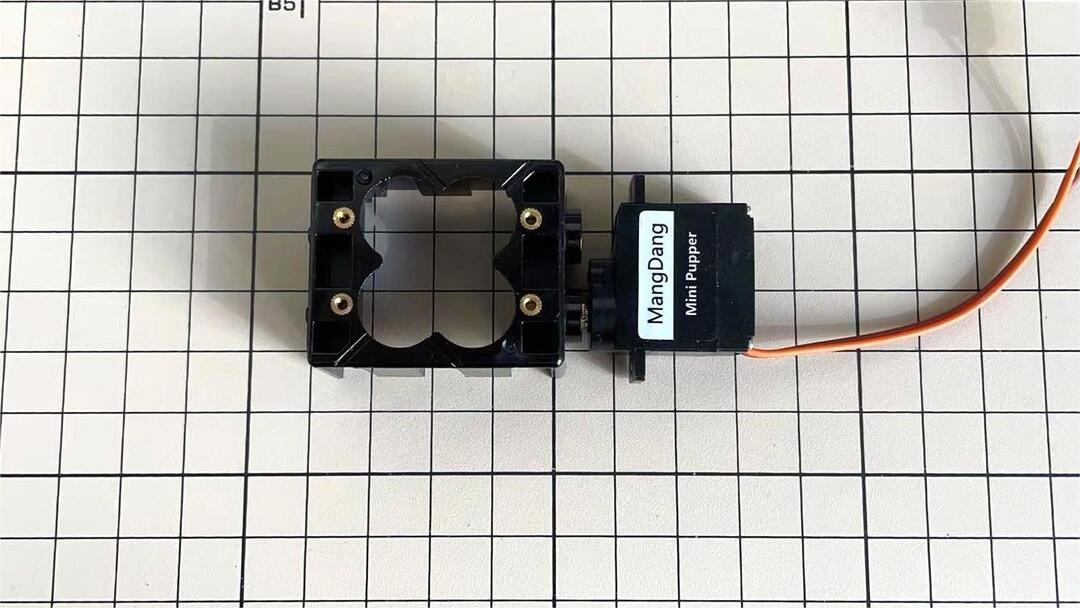

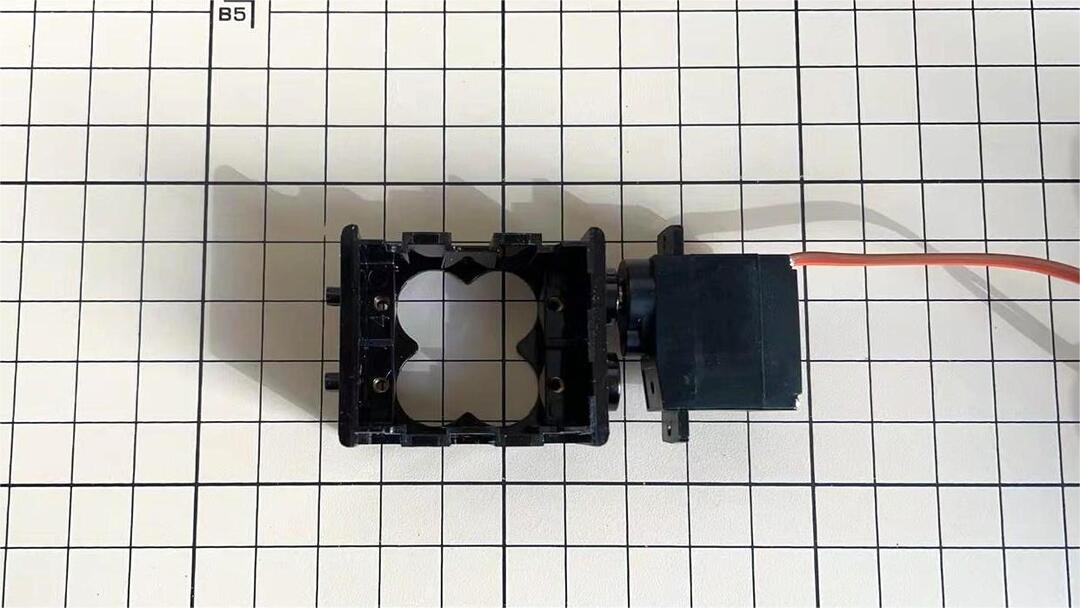

Put two servos into hip parts

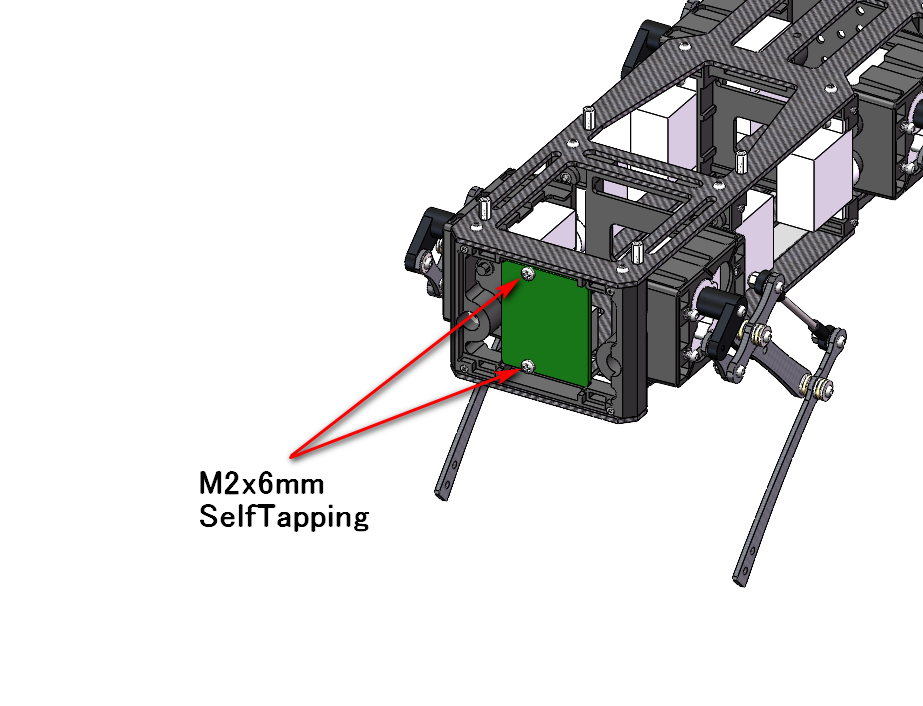

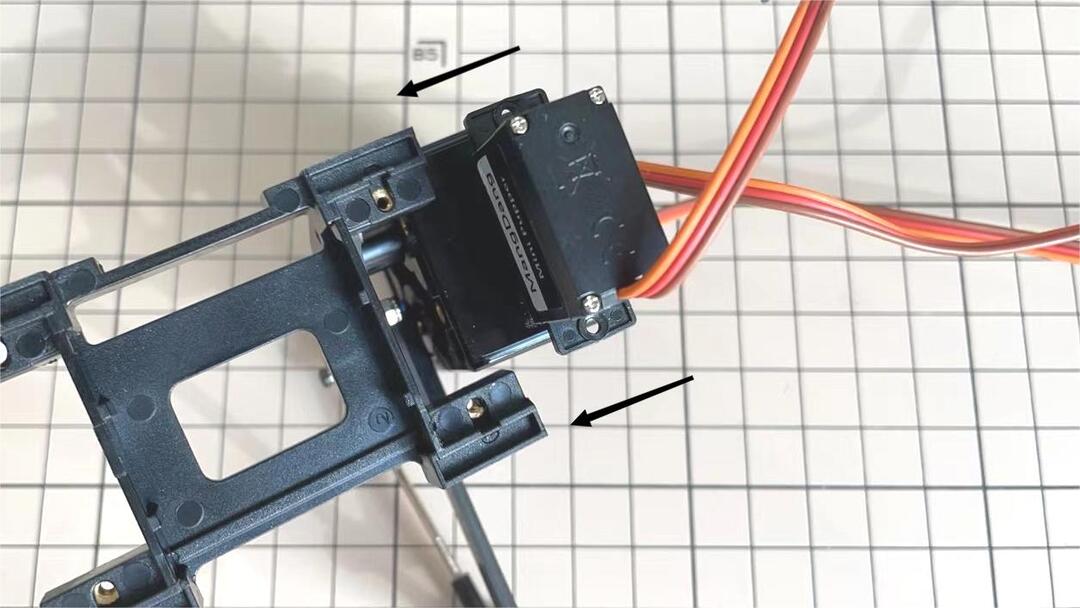

Insert two servos into the box and fix them with M2x6mm screws.

Four hip parts, please refer to the servo positions.

Assemble leg and hip

※ If you have no technology background, it’s easier to attach the leg to the hip during the calibration step.

※ If you are the first time to assemble quadruped robot, we don’t recommand you use the Loctite.

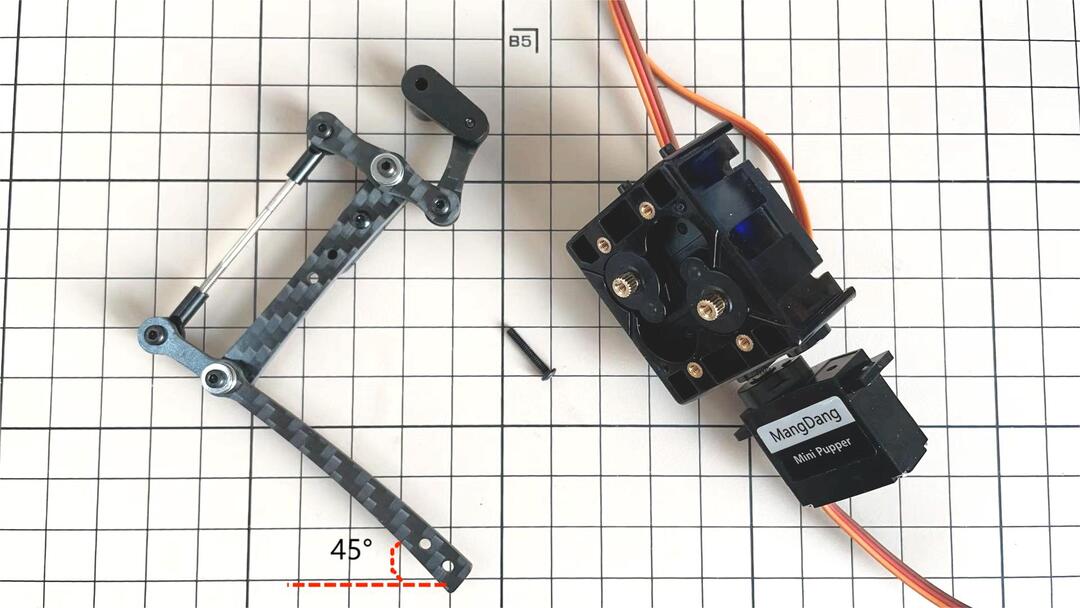

Attach the leg to the hip using the M2x12mm screws. Leg is tilted at approximately 45°, as shown in the manual.

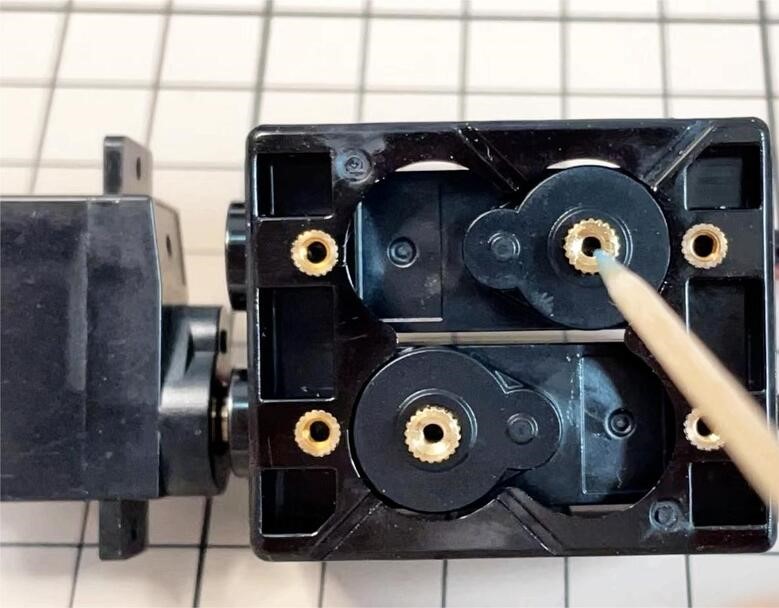

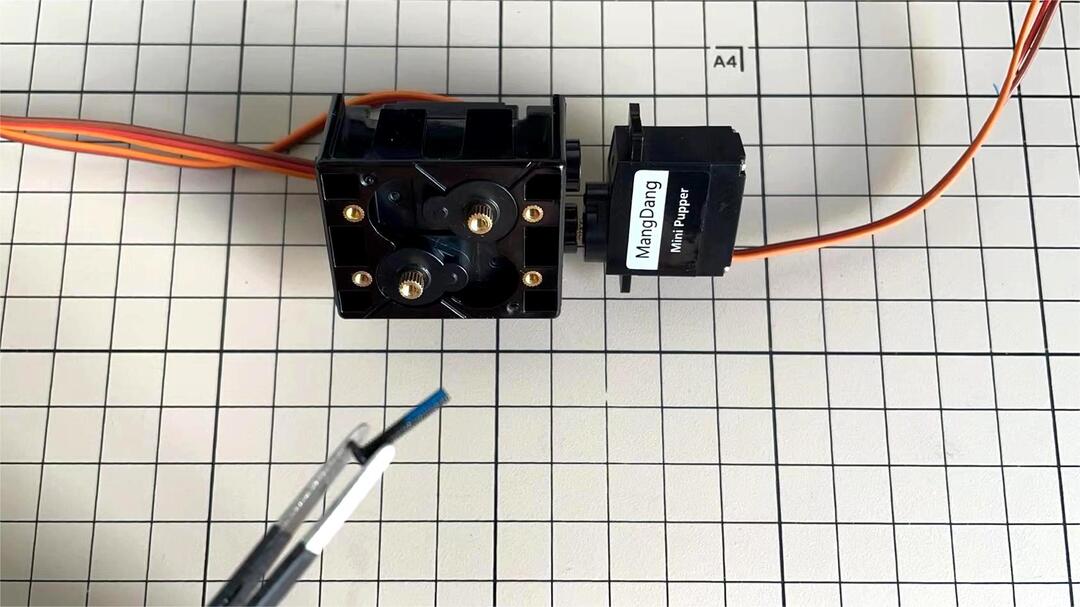

Tighten the screws with Loctite. Use a toothpick to apply Loctite to the servo’s screw holes.

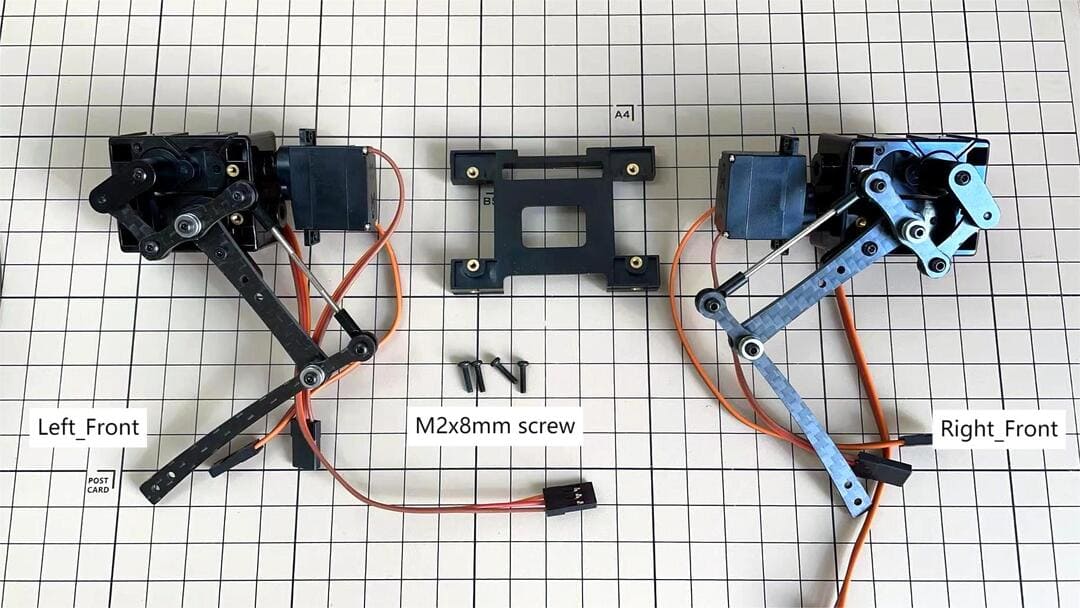

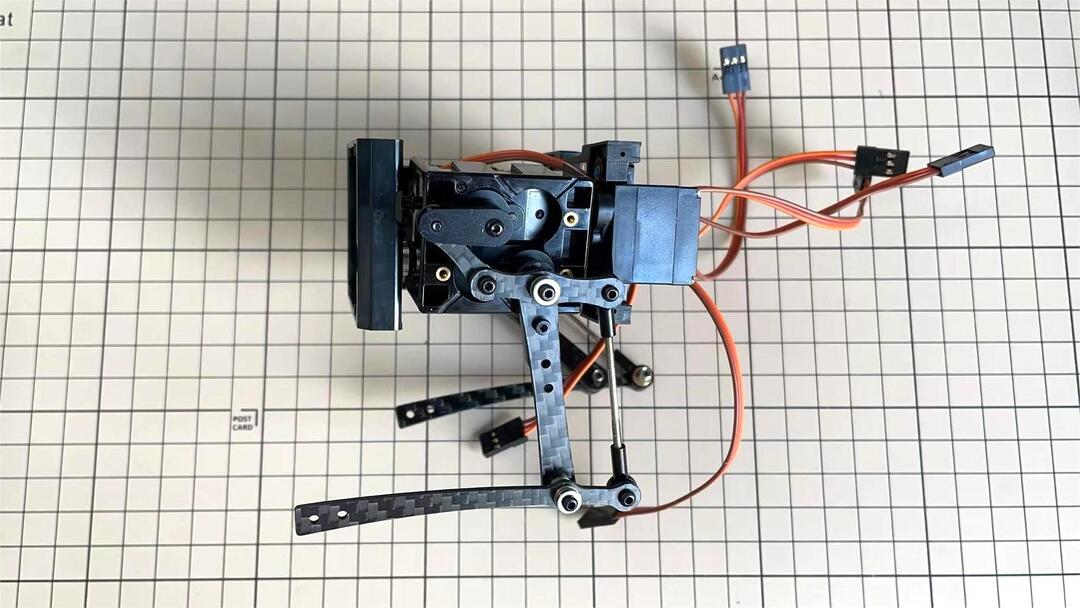

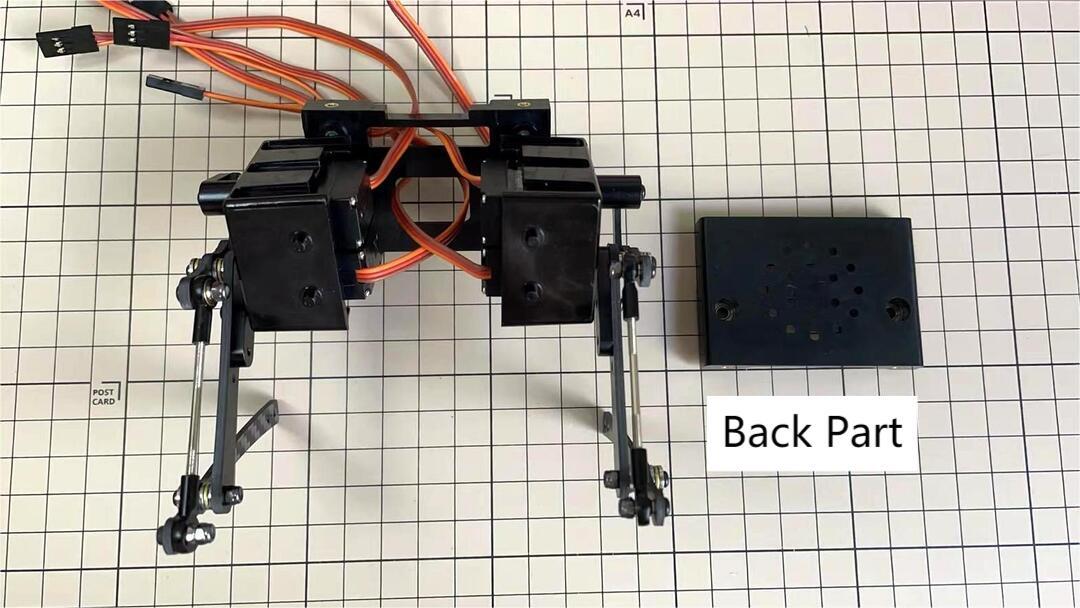

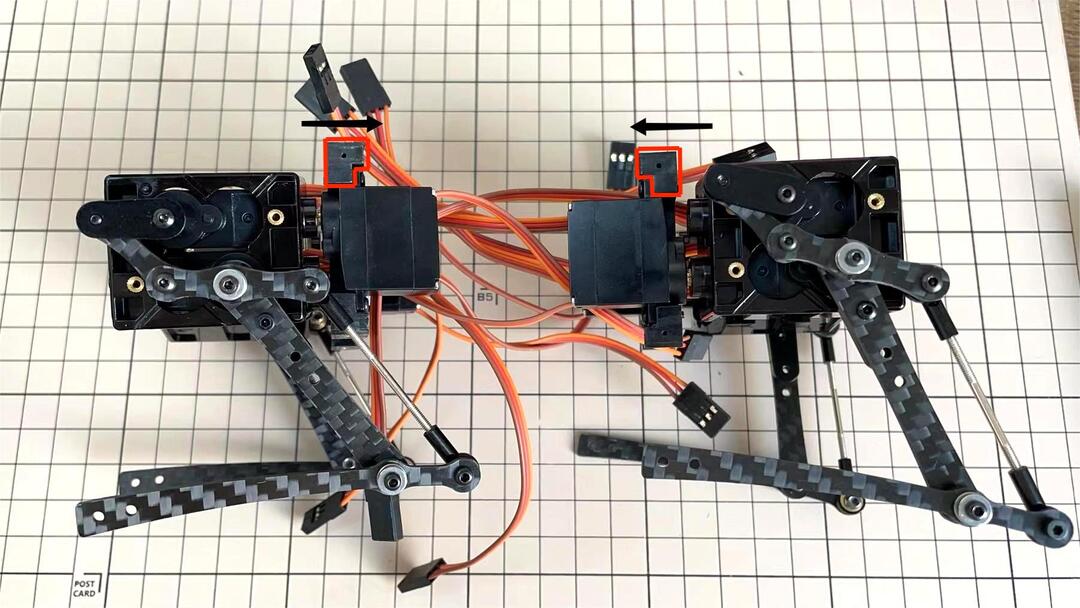

Step 4.2 Four Hips

※ Please pay attention to the positions of the servo gear output shaft

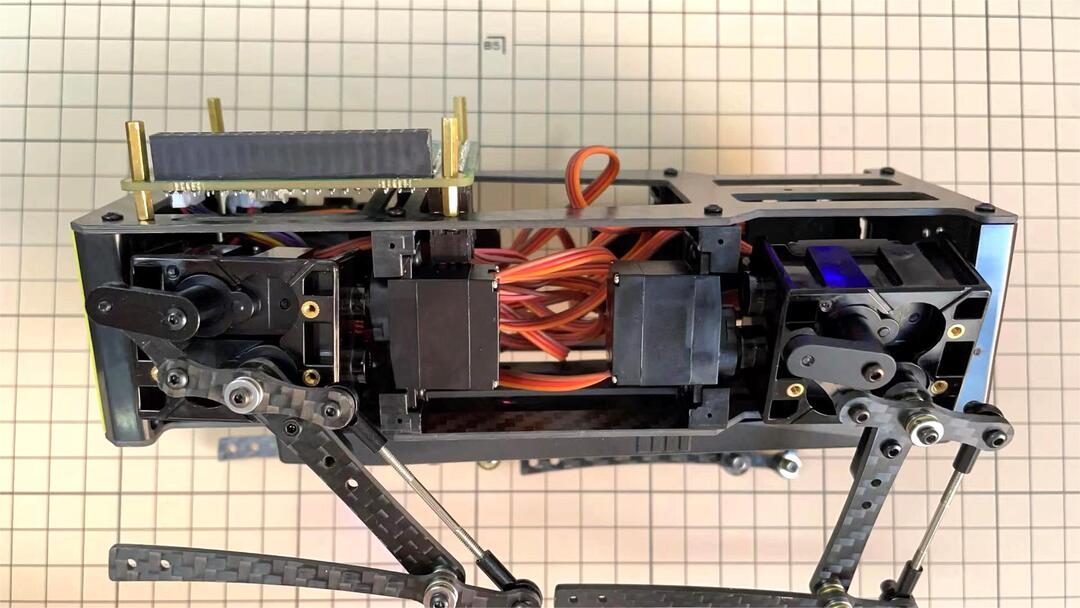

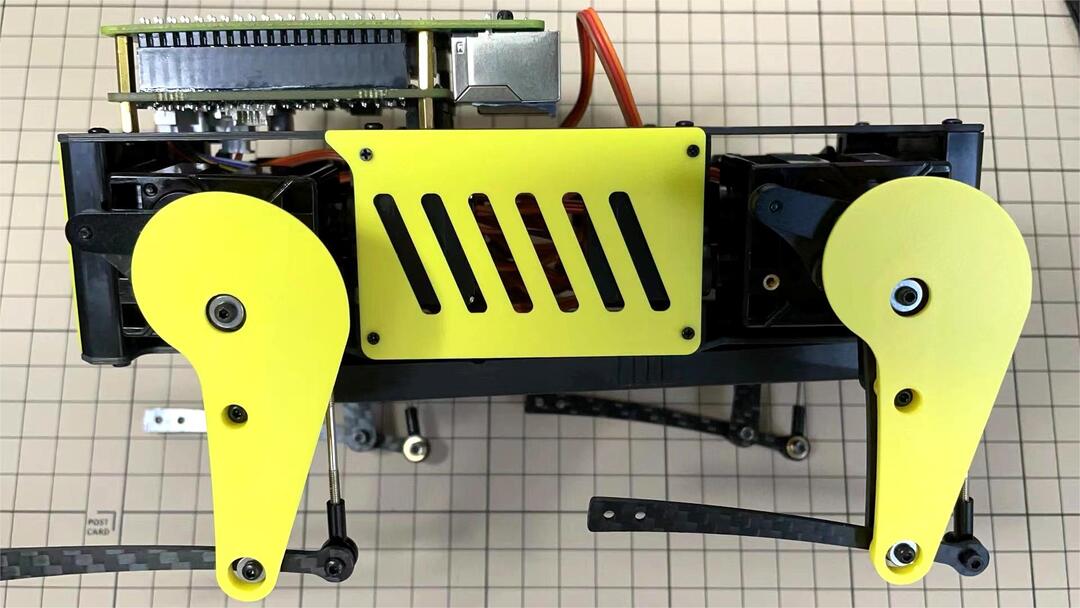

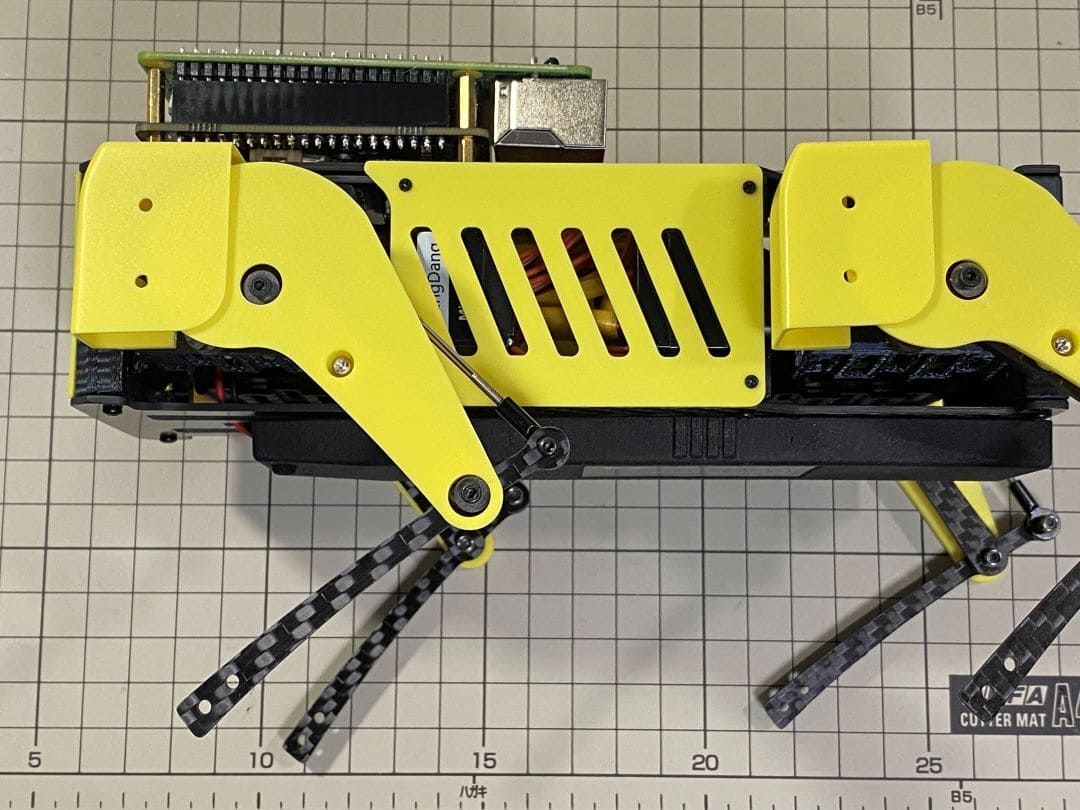

5. Body Frame Assembly

Step 5.1 Center parts

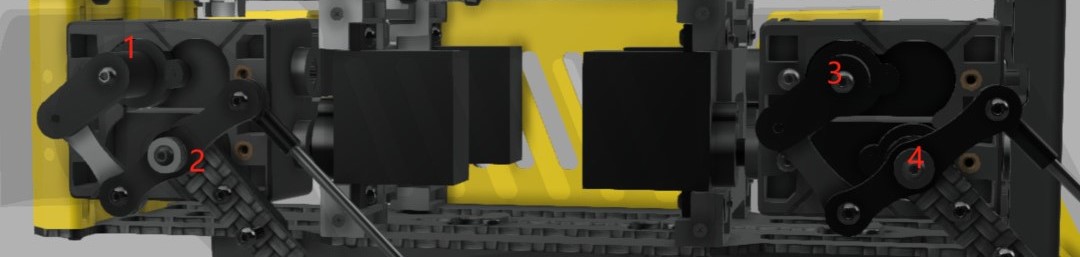

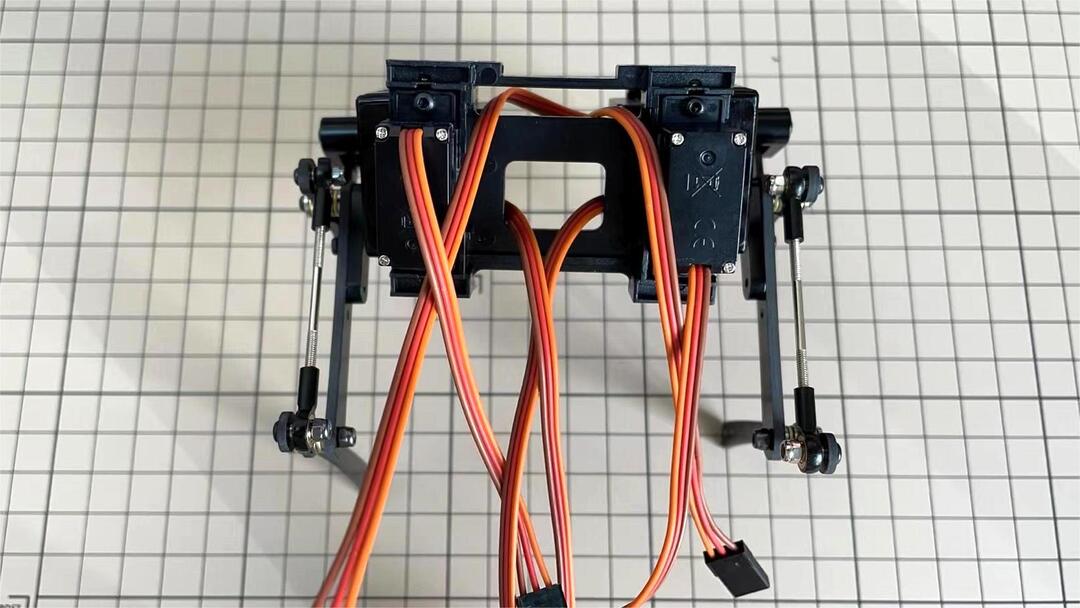

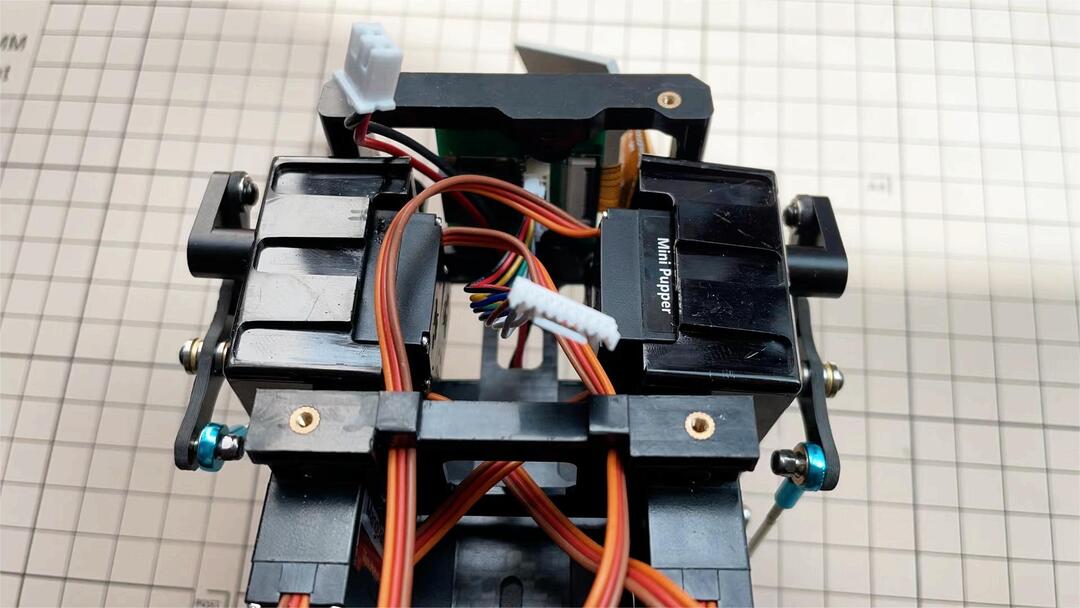

The position of each servos are shown as below.

※ There are two kinds of servo cables, No.1,4,7,10 cables length is 9cm, other cables length is 15cm.

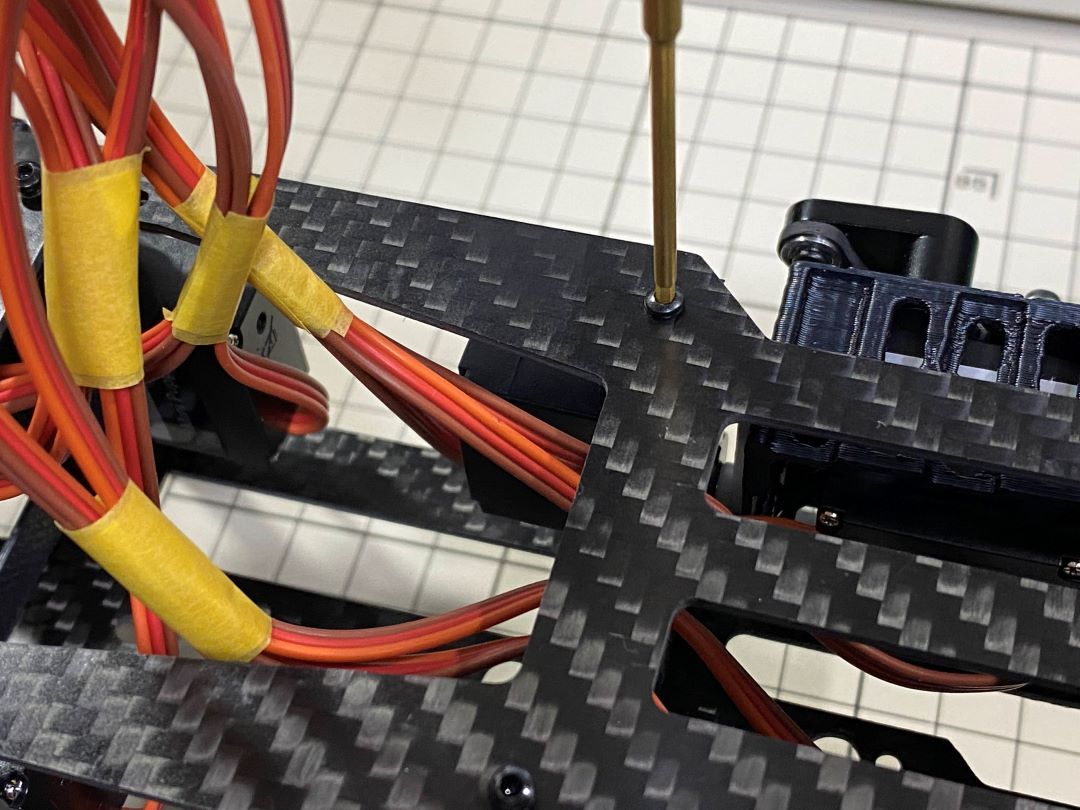

It is useful to put masking tape on the cables and write the number of servos during this process to make it easier later.

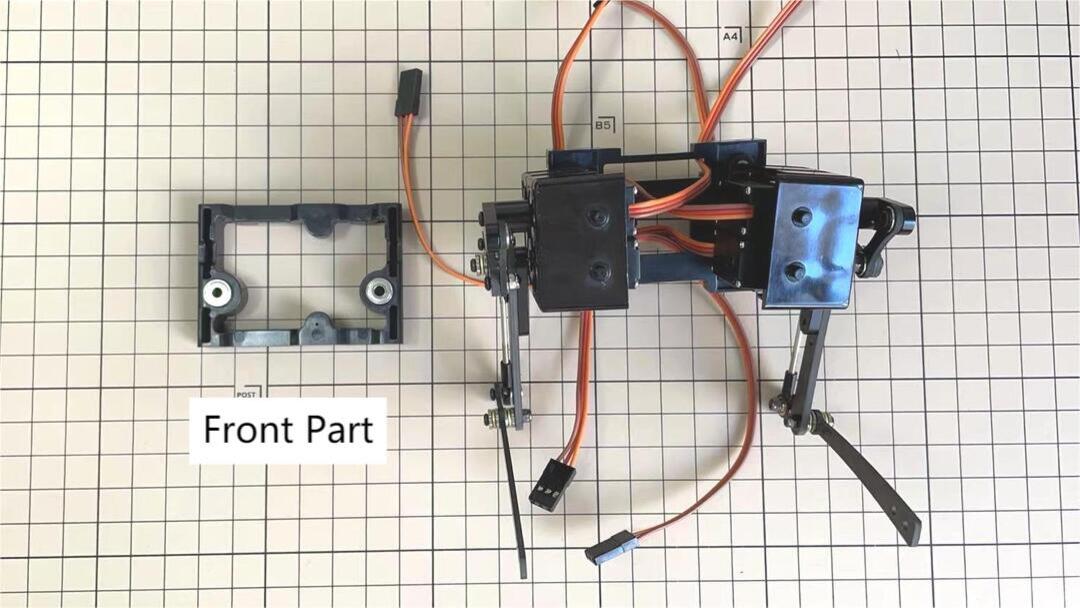

Step 5.2 Front parts

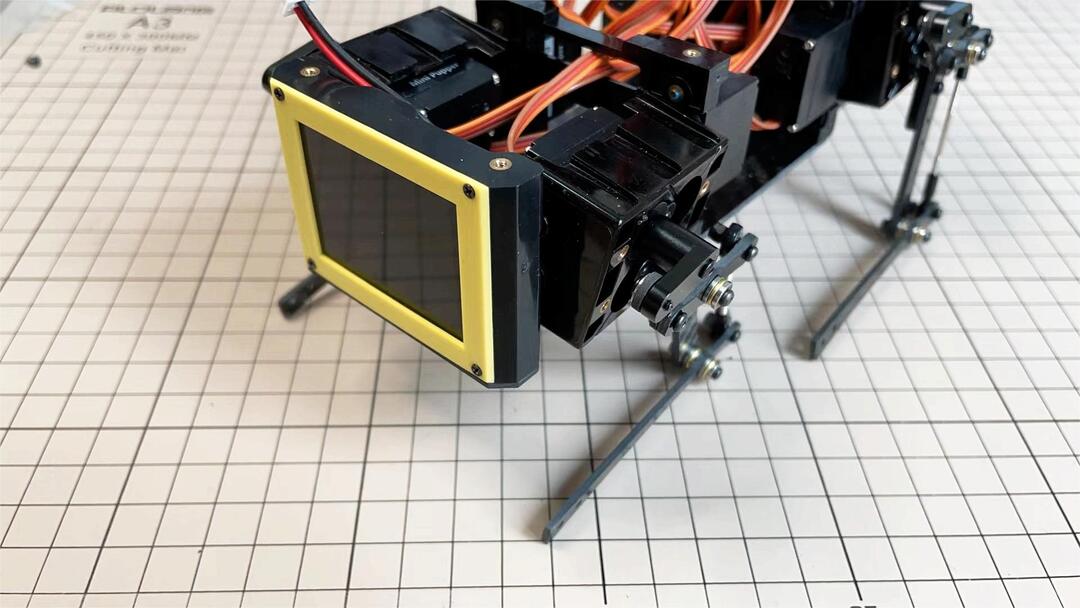

*The front part is designed to hold the LCD screen. Make sure you don’t mistake it for the rear part.

Step 5.3 Rear side

The same procedure as for the front part.

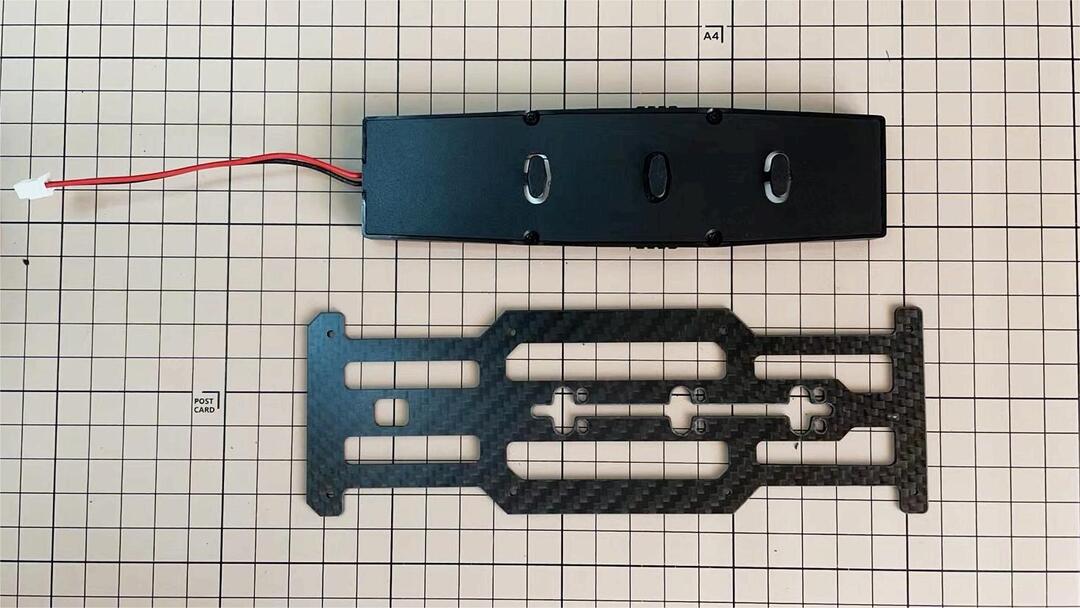

Step 5.4 Battery

If you DIY the battery, please ensure our battery spec at first, especially the Voltage should be less than 7.4V, you can also refer to other backers work https://www.facebook.com/groups/716473723088464/posts/777616293640873/

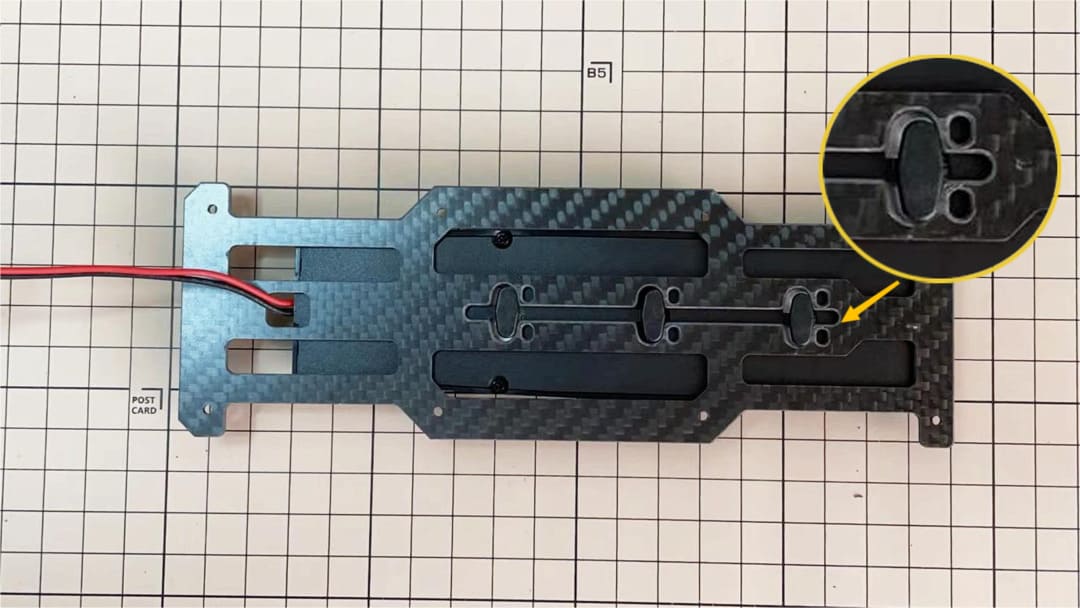

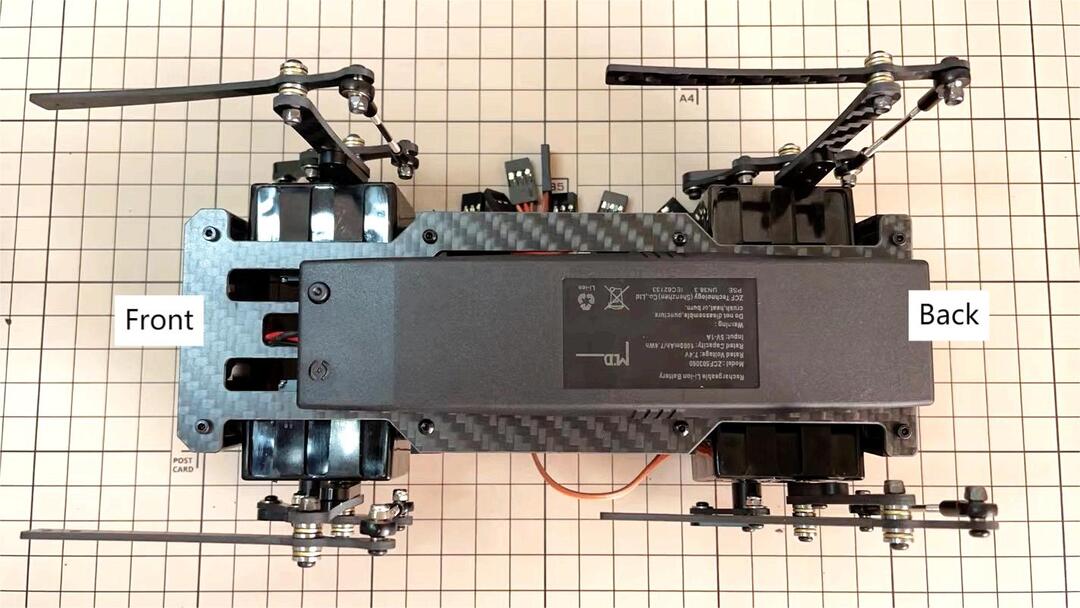

Install the battery pack.

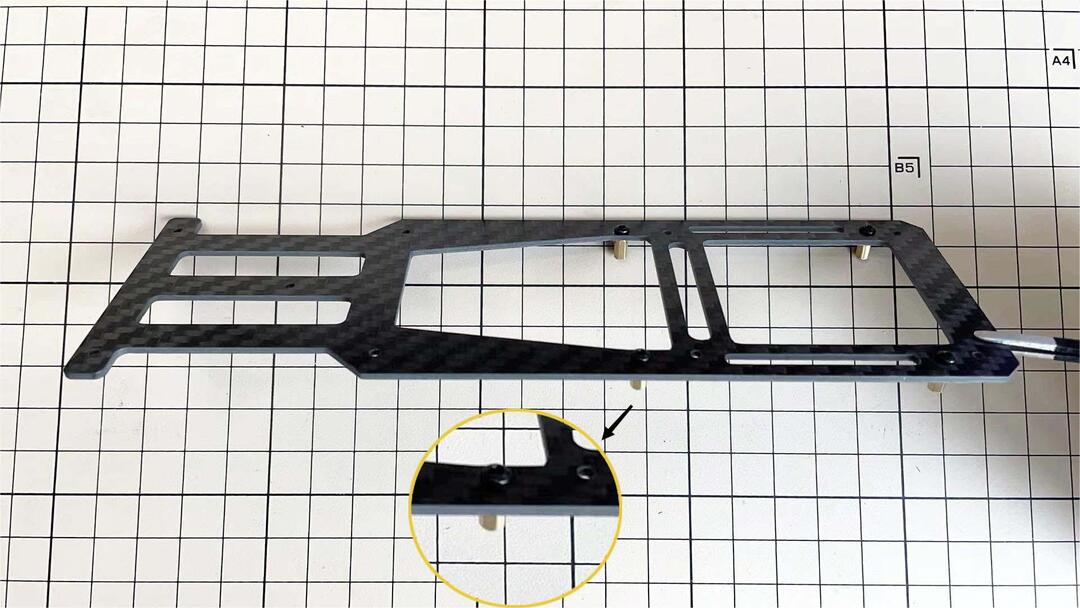

Be careful of the carbon fiber front and rear orientation.

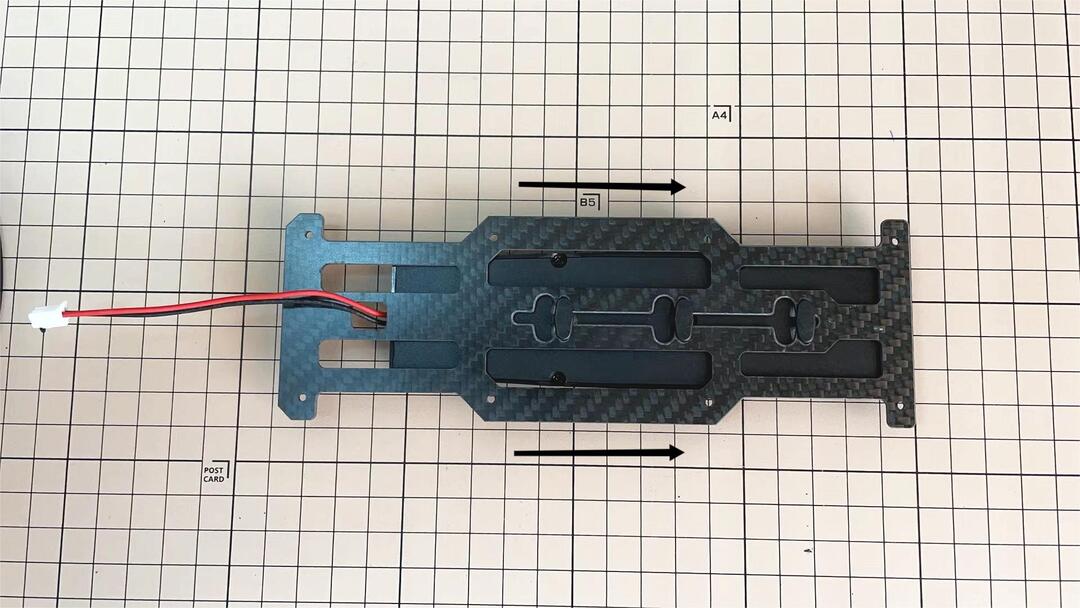

Slide the battery backwards and secure it. Pass the cable through the hole in the bottom plate and bring it up to the top.

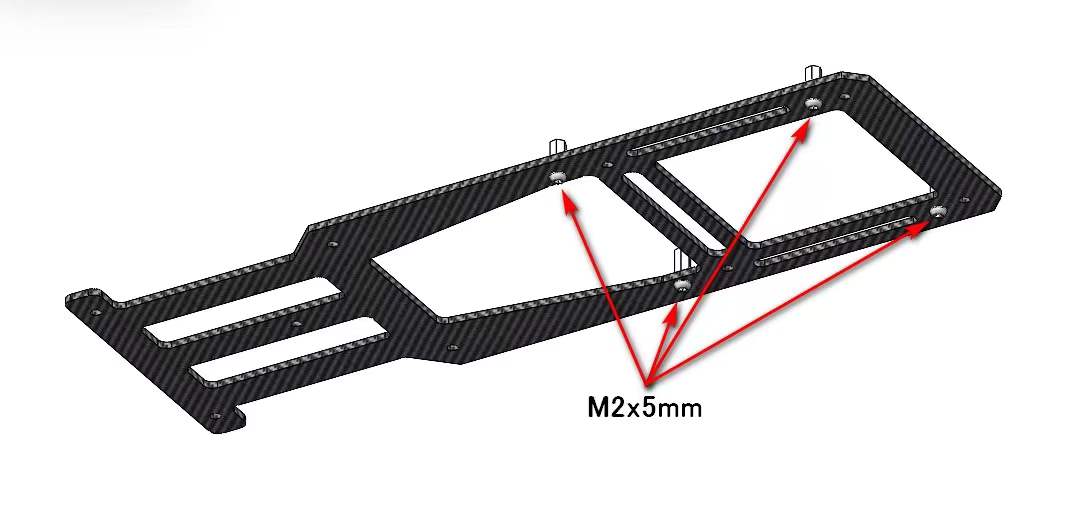

Step 5.5 Bottom plate

The orientation of the plate must be such that the hole is at the front.

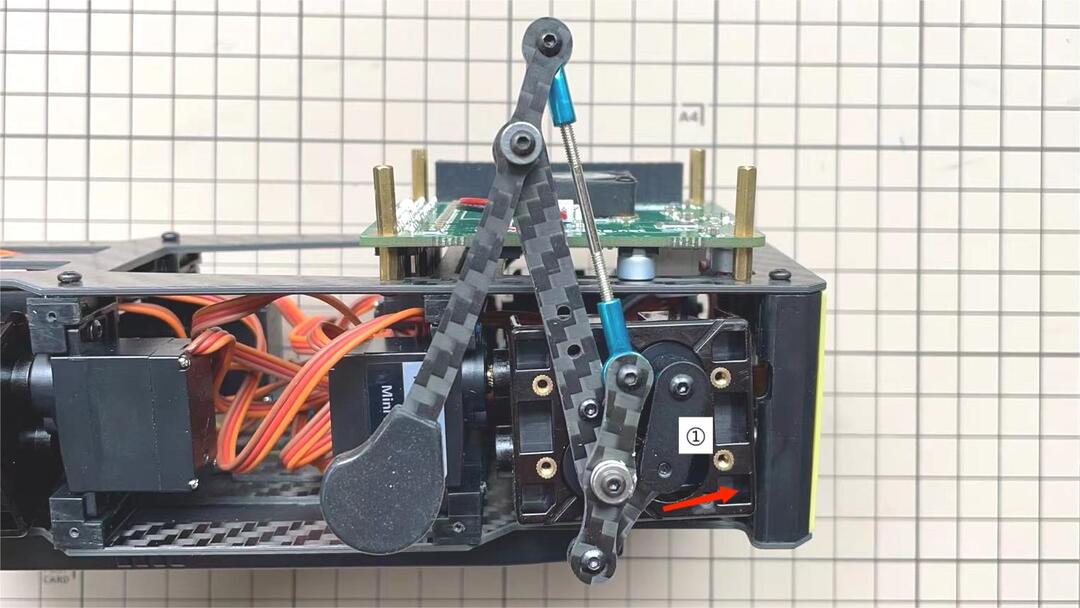

If the leg is stuck, turn the part ①

Step 5.6 Display and Frame of face

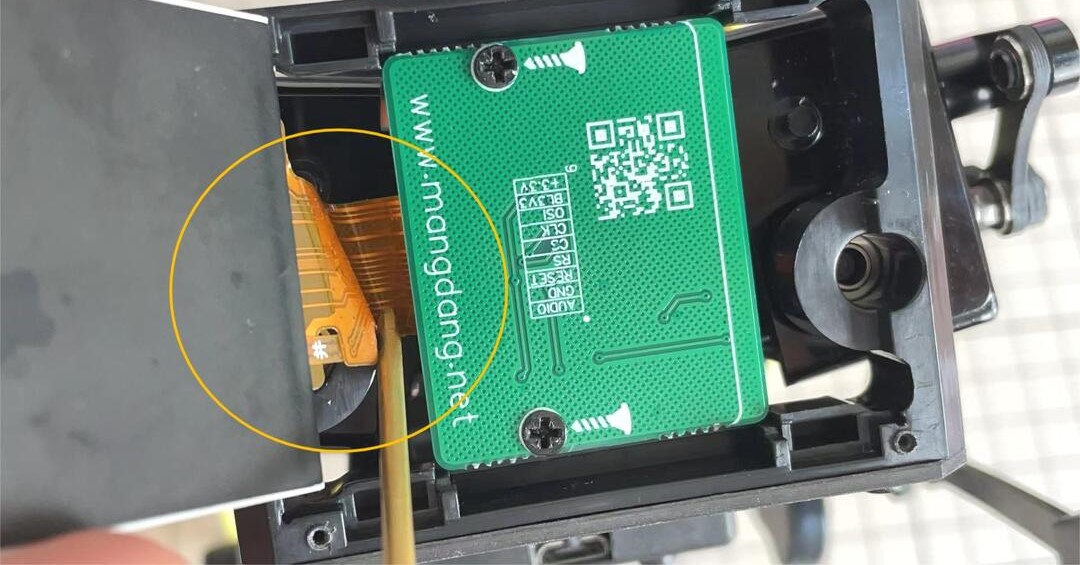

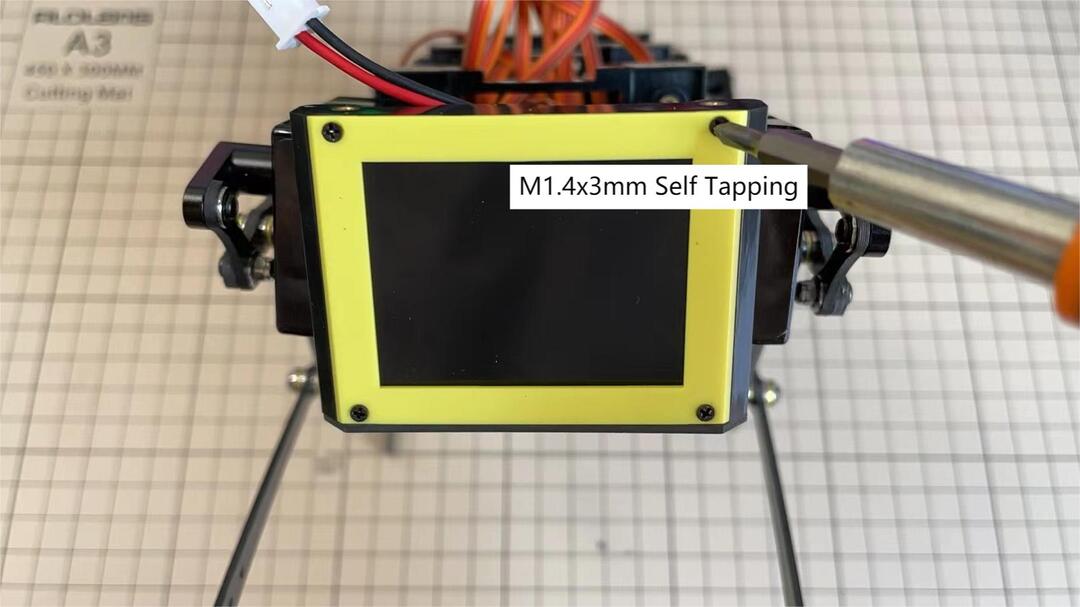

Remove the protective sheet for the display. Fold the thin flexible cable at the edge of the display. Attach the board and the display to the main unit. When attaching the display, you can use a stick to gently push the flexible cable, so that it goes as far back as possible.

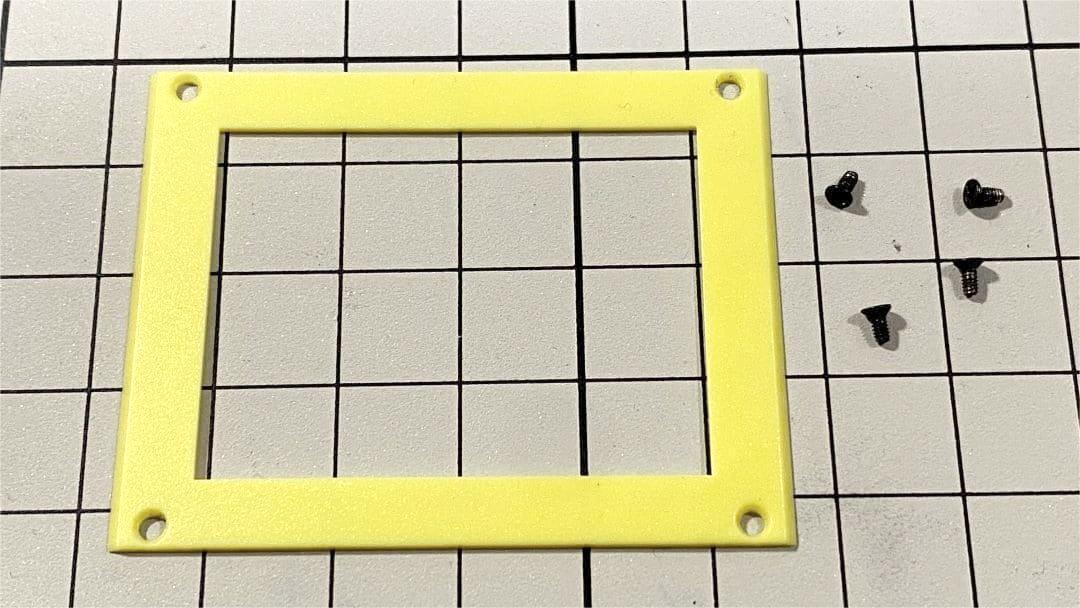

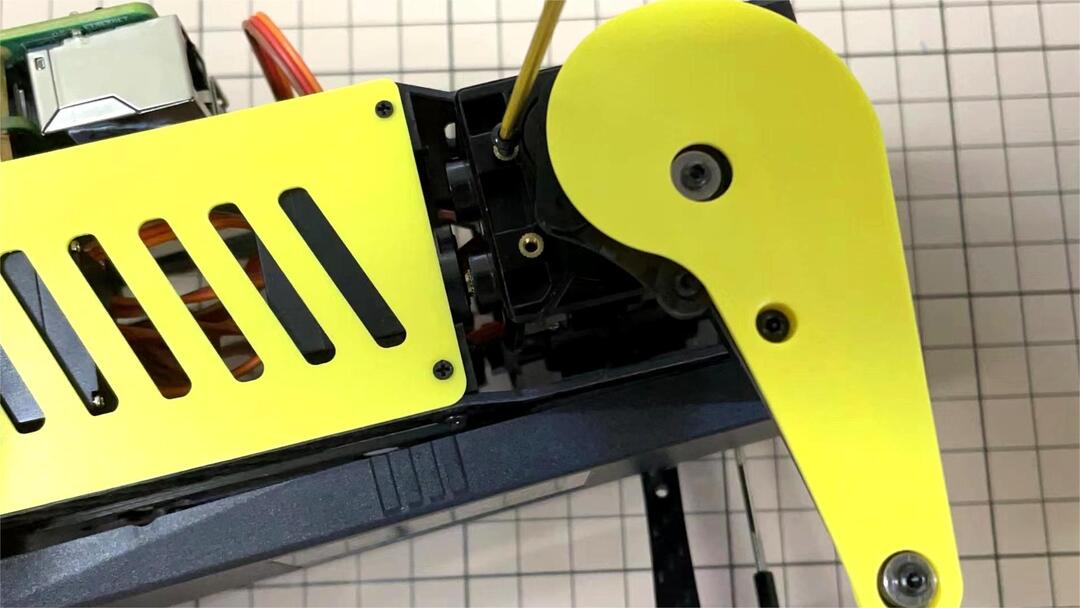

Be careful with the yellow parts as it has a front and back.

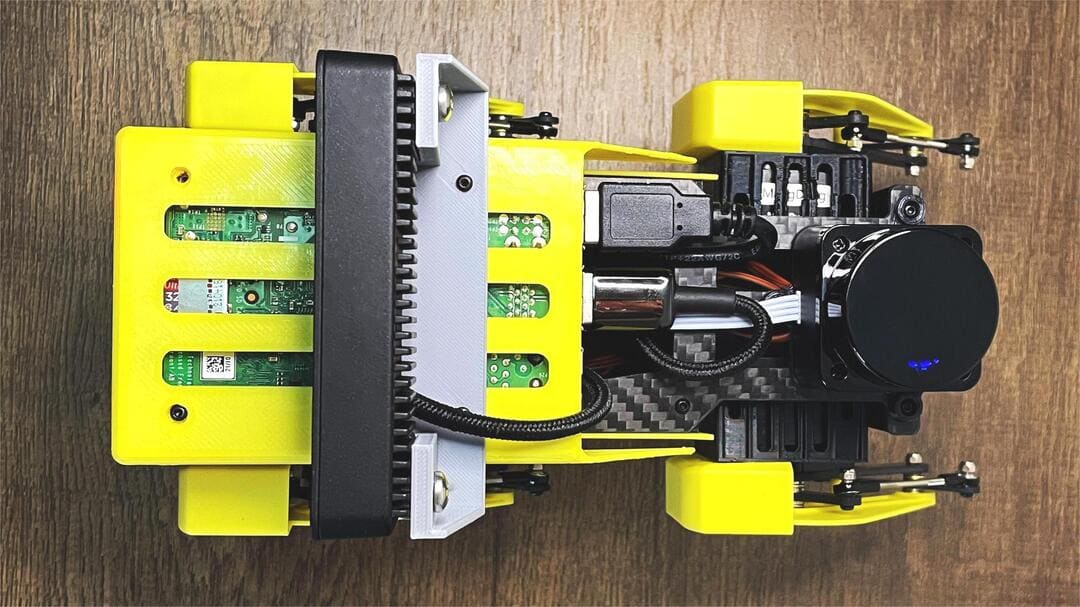

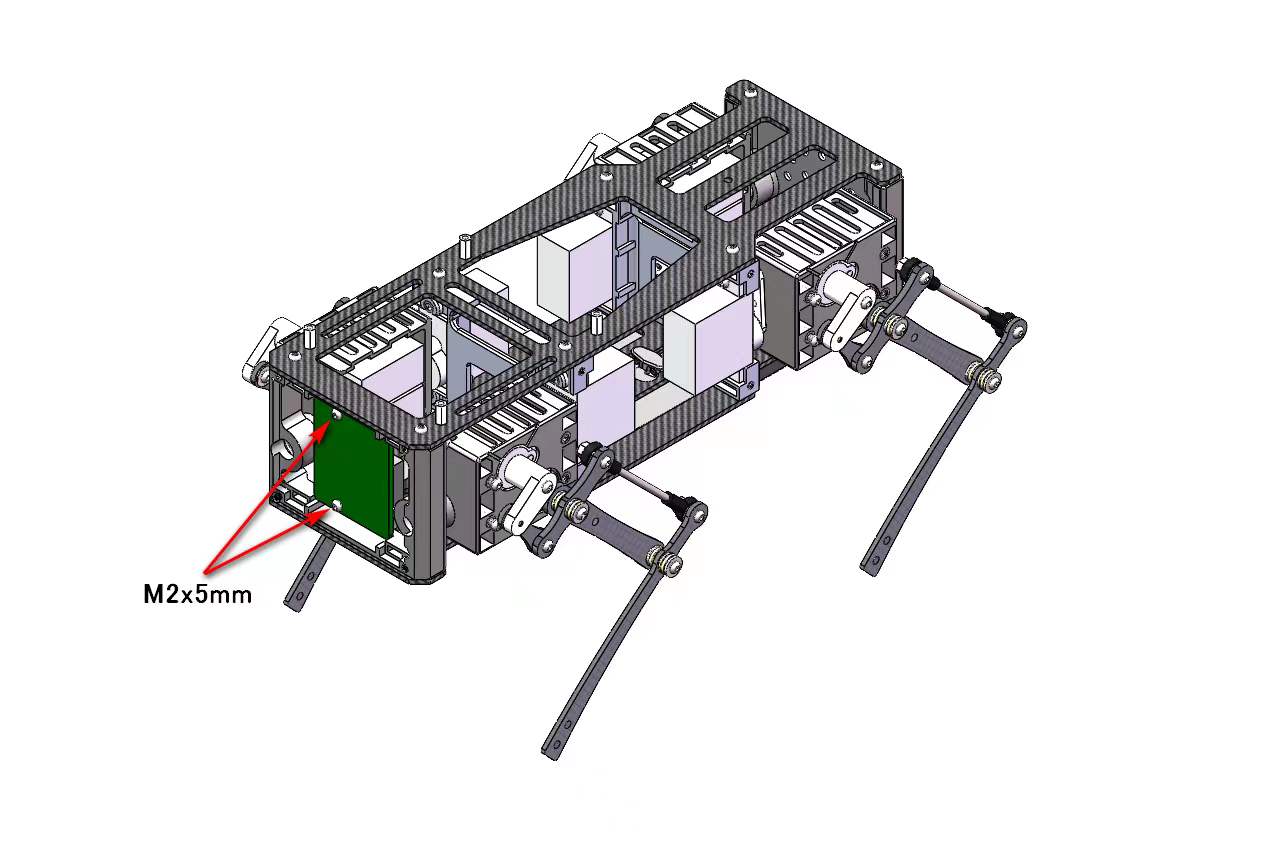

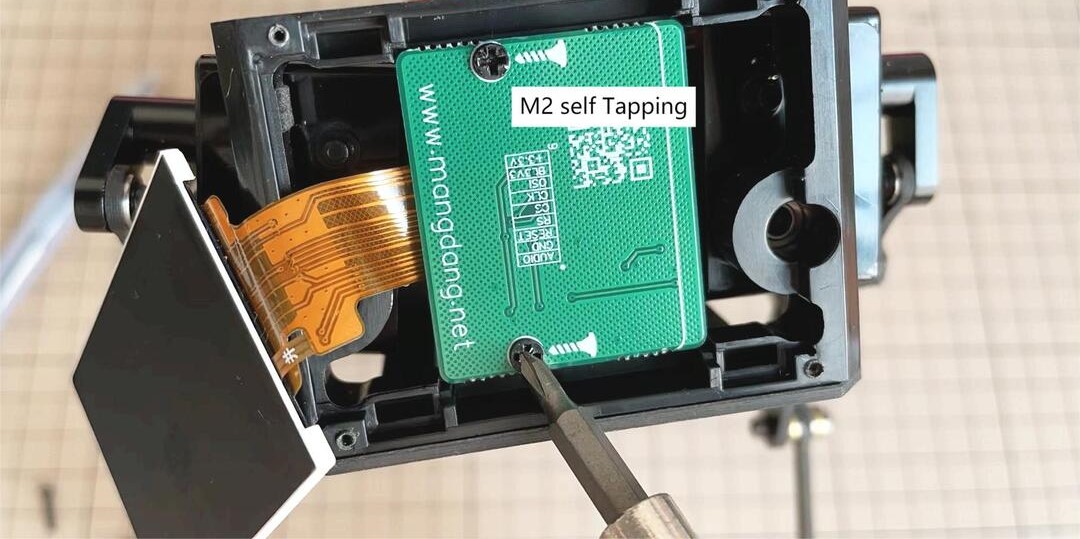

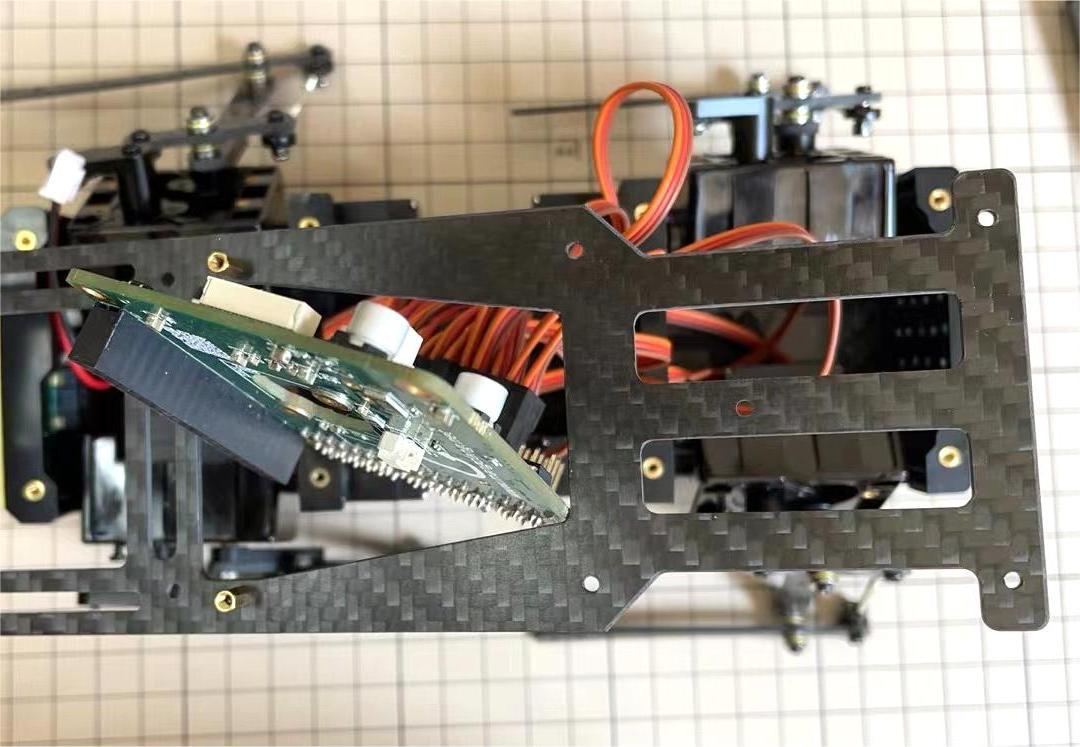

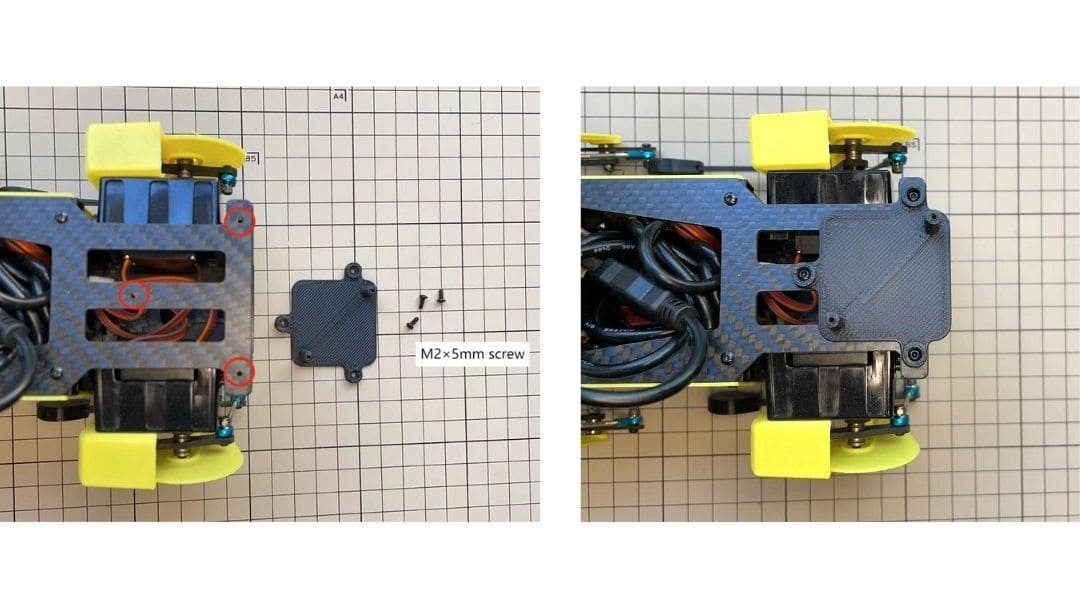

Step 5.7 Custom circuit board

Plug the display cable into the custom circuit board.

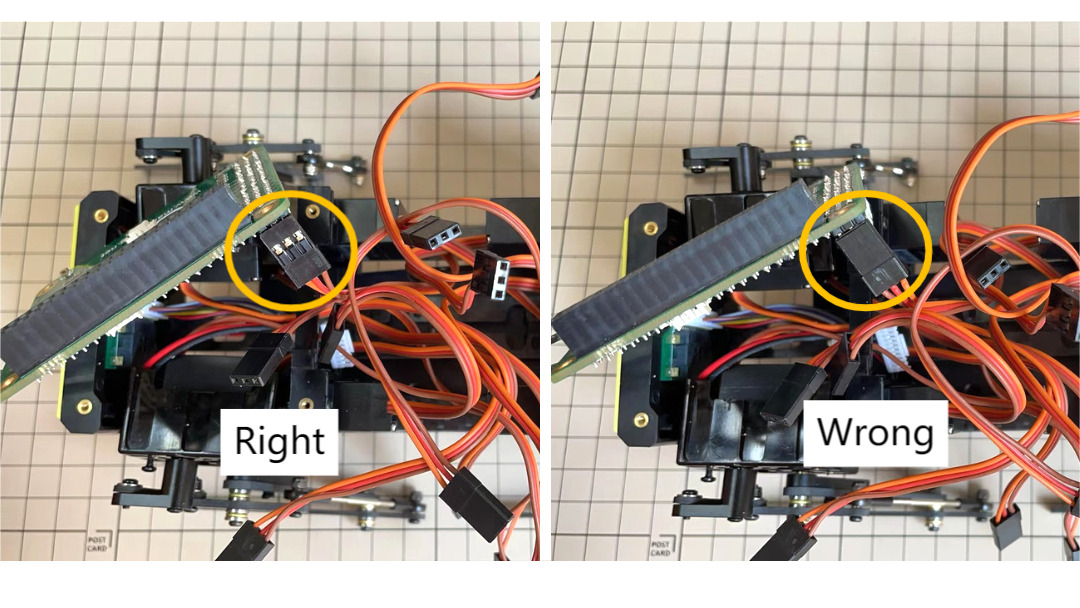

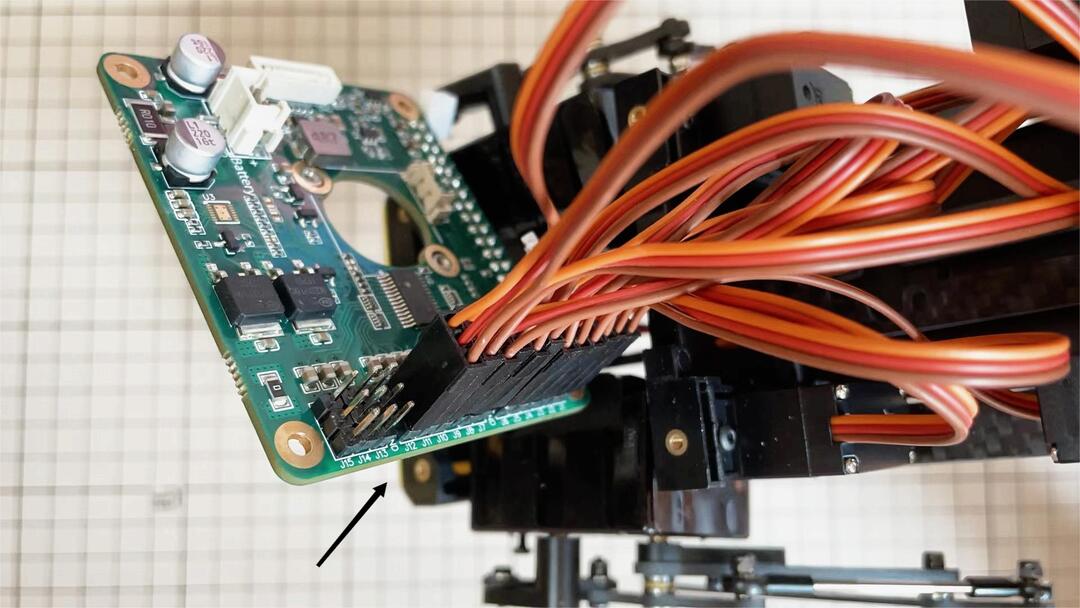

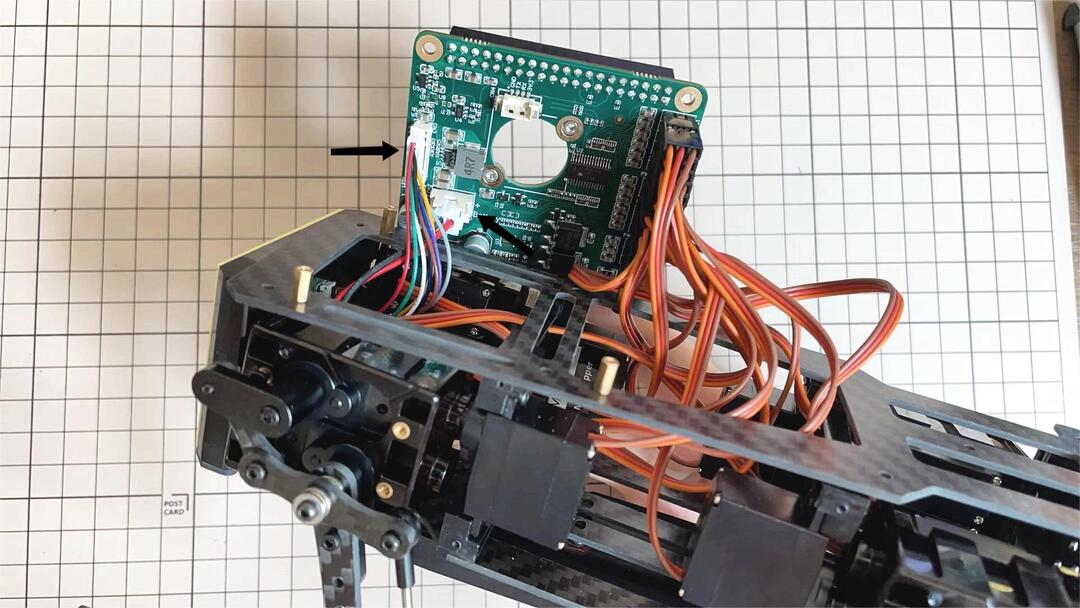

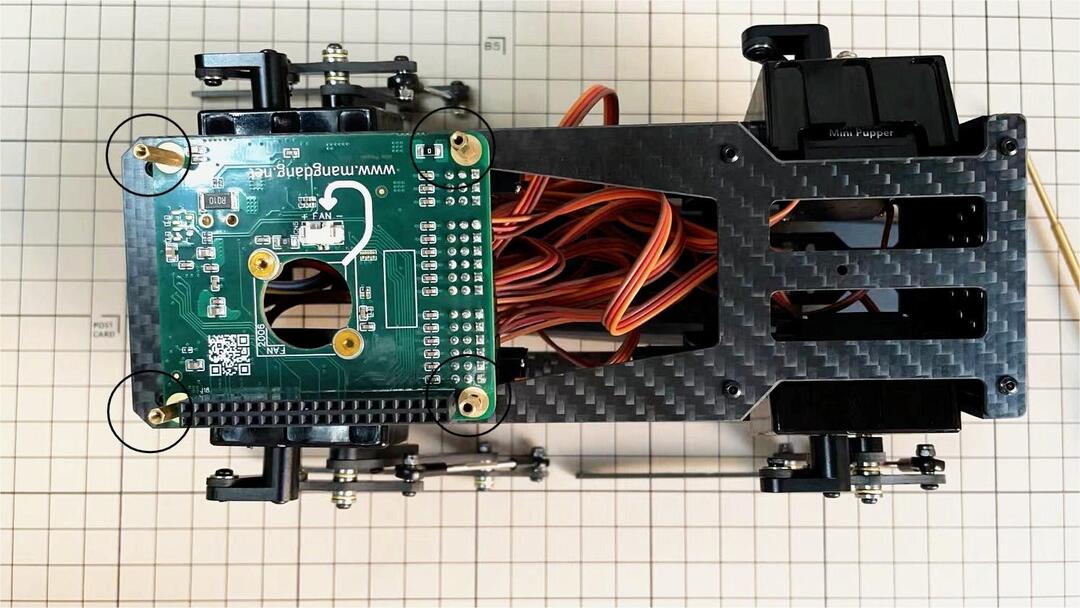

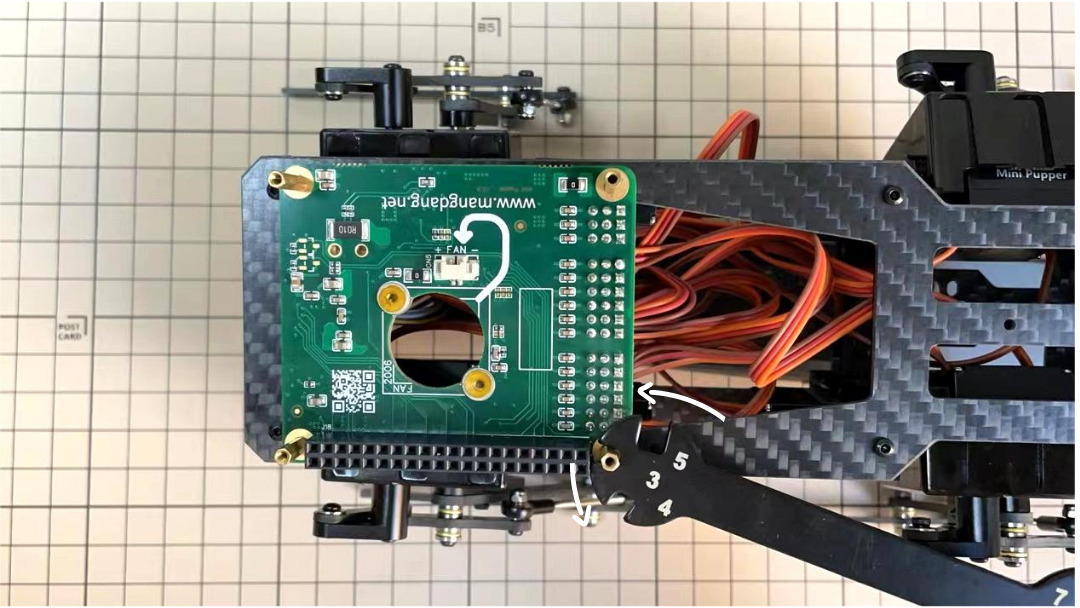

Insert the 12 servo cables. In the picture, you can see: J1,J2,J3…. . J12.

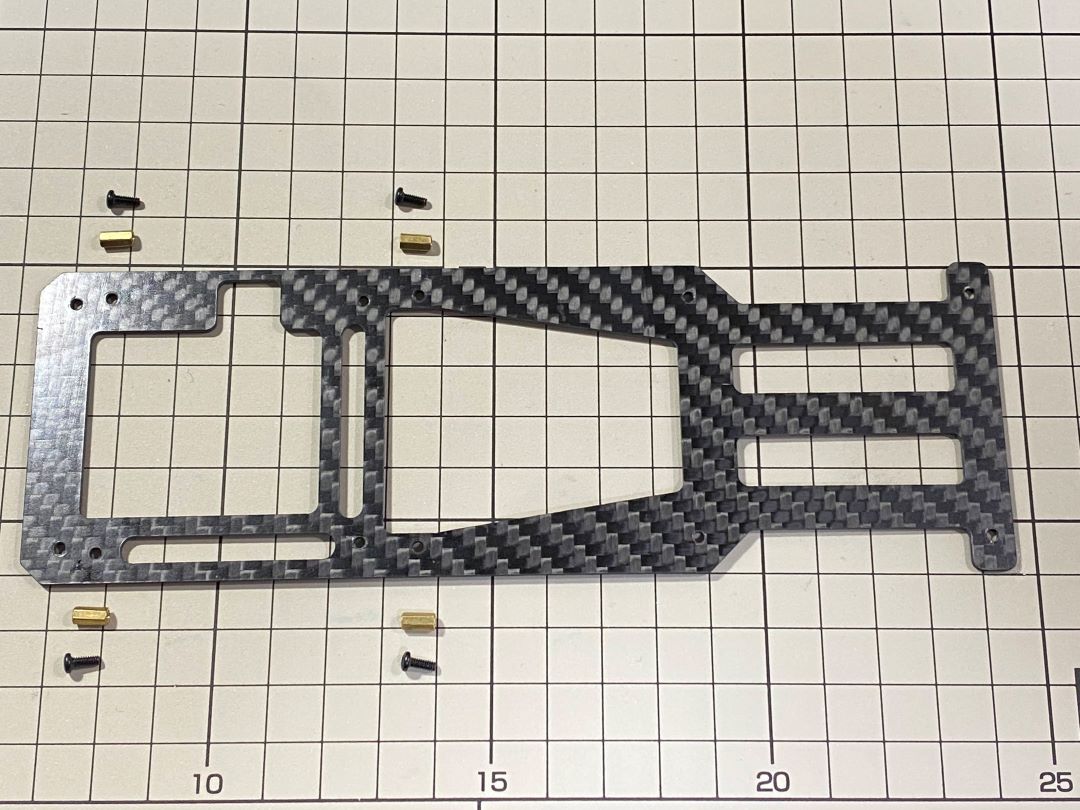

Use four M2x5mm screws and four short supports.

put on the carbon fiber board

plug in the battery cable. This connector may interfere with the hips parts, so you have to slide it through a hole in the middle of the board.

Use eight M2x5mm screws. The orientation of the plate must be such that the large opening is at the front.

Pull the custom circuit board closer to the body. The board may float, but you can use four long posts to hold it in place.

※ Need to pay attention to the cable of the No. 1 servo to prevent it from being overwhelmed.

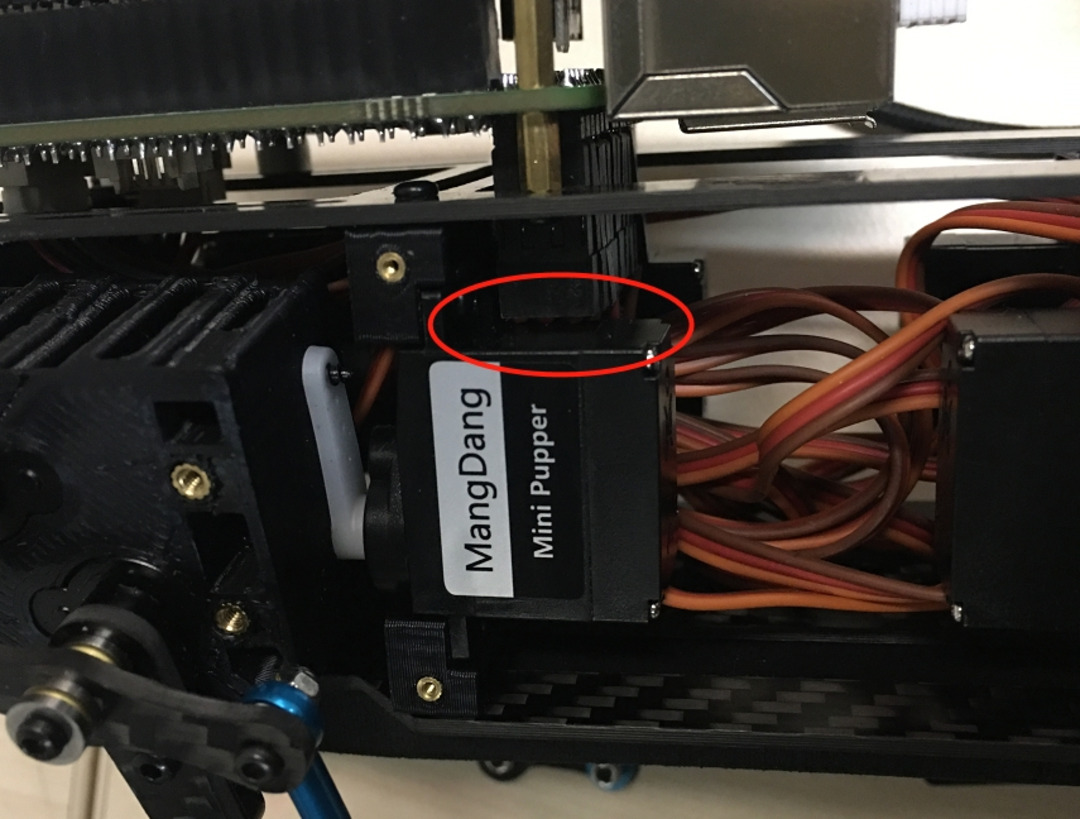

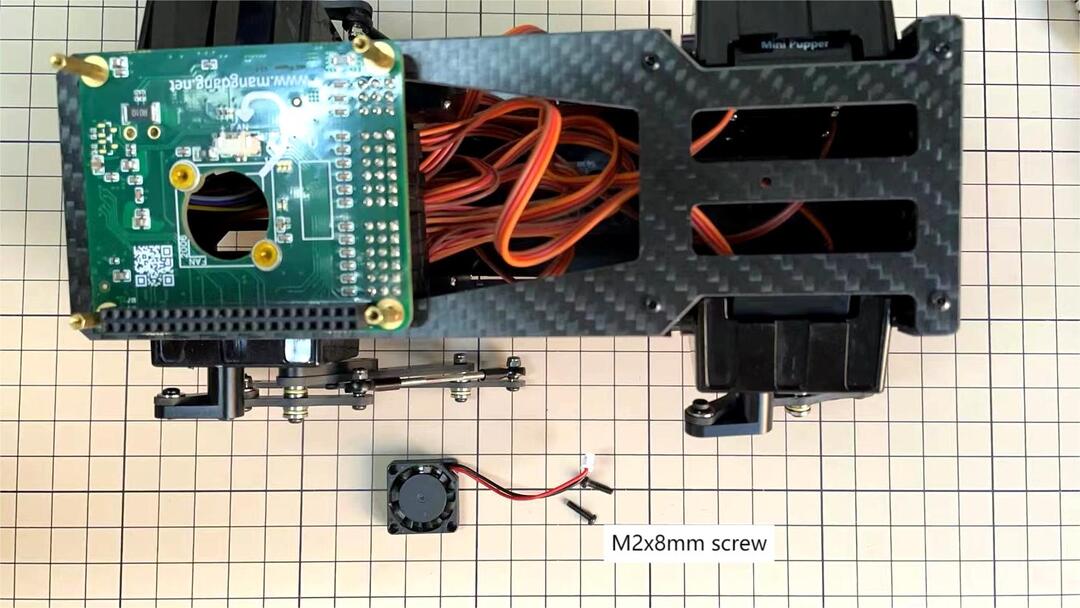

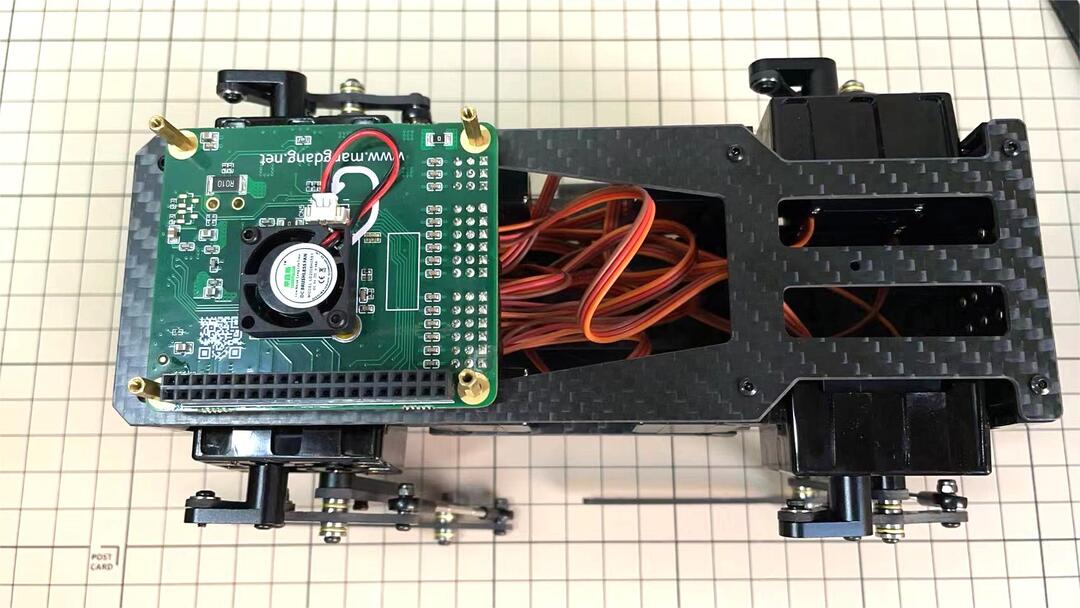

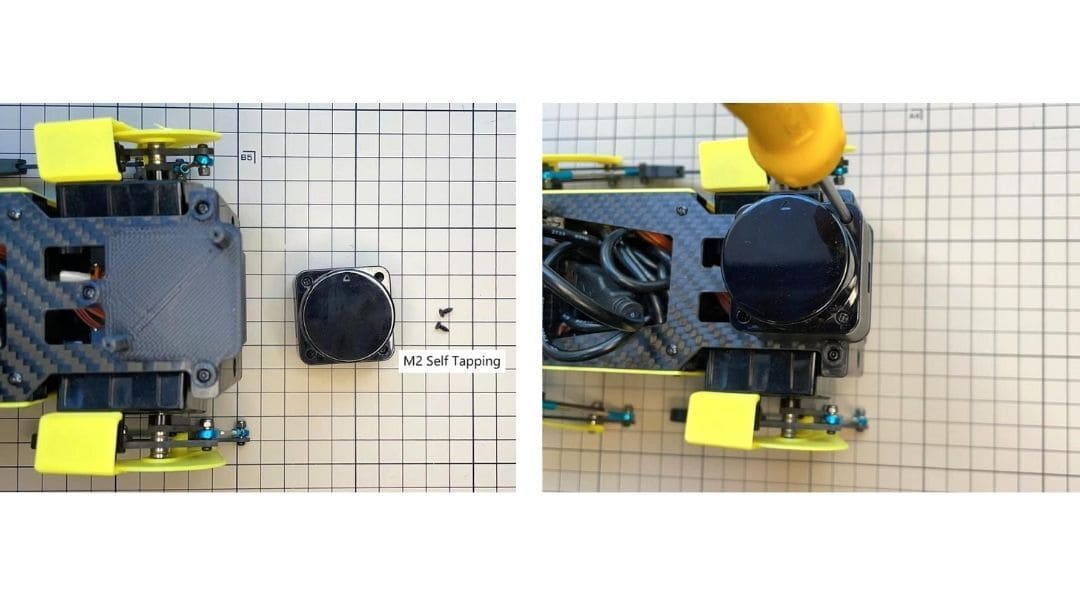

Step 5.8 Fan

To install the fan.

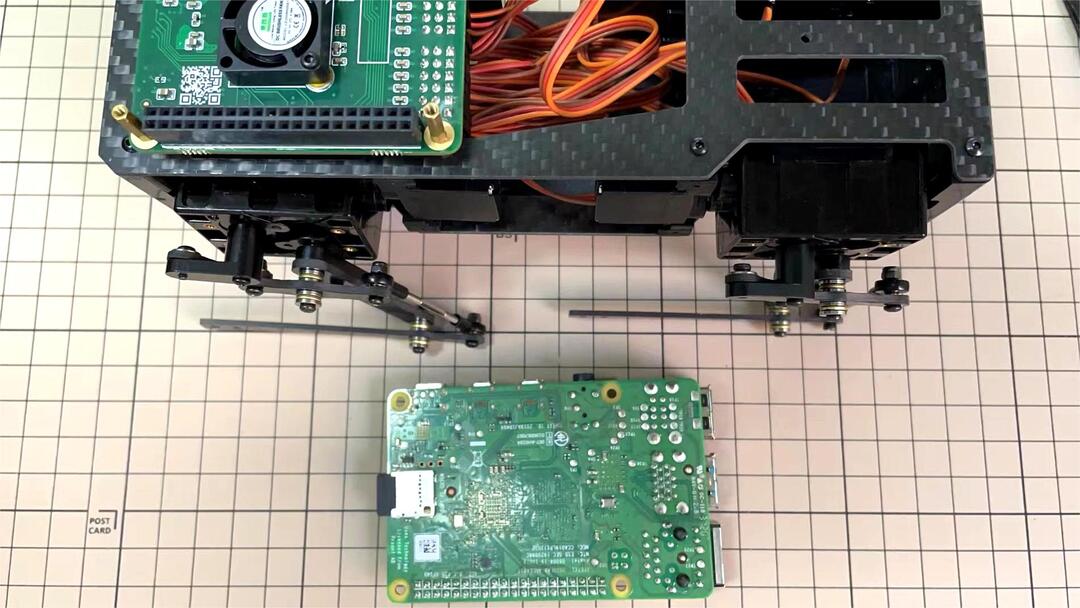

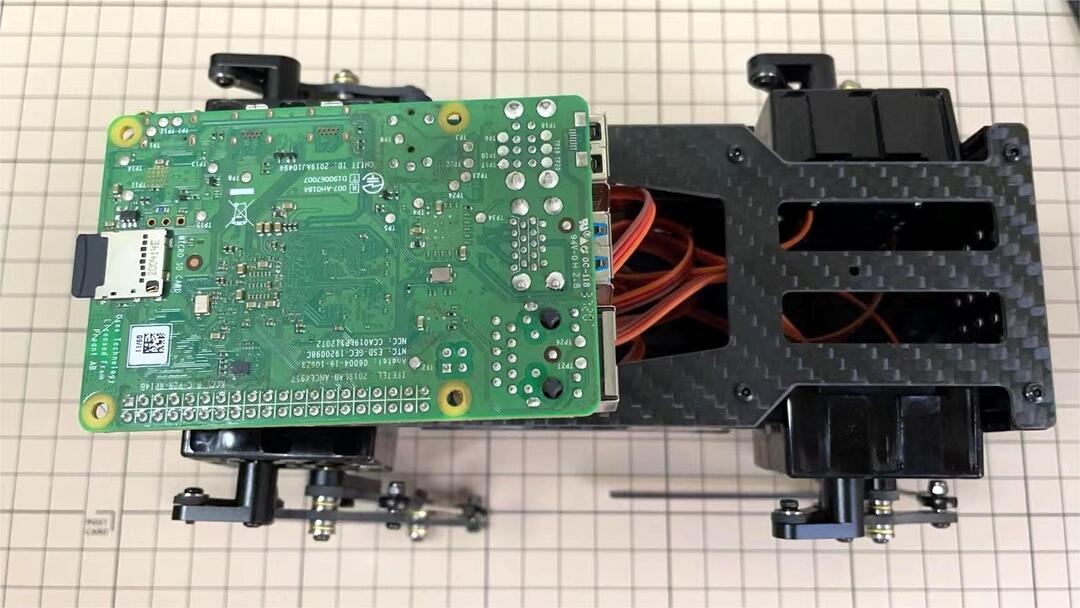

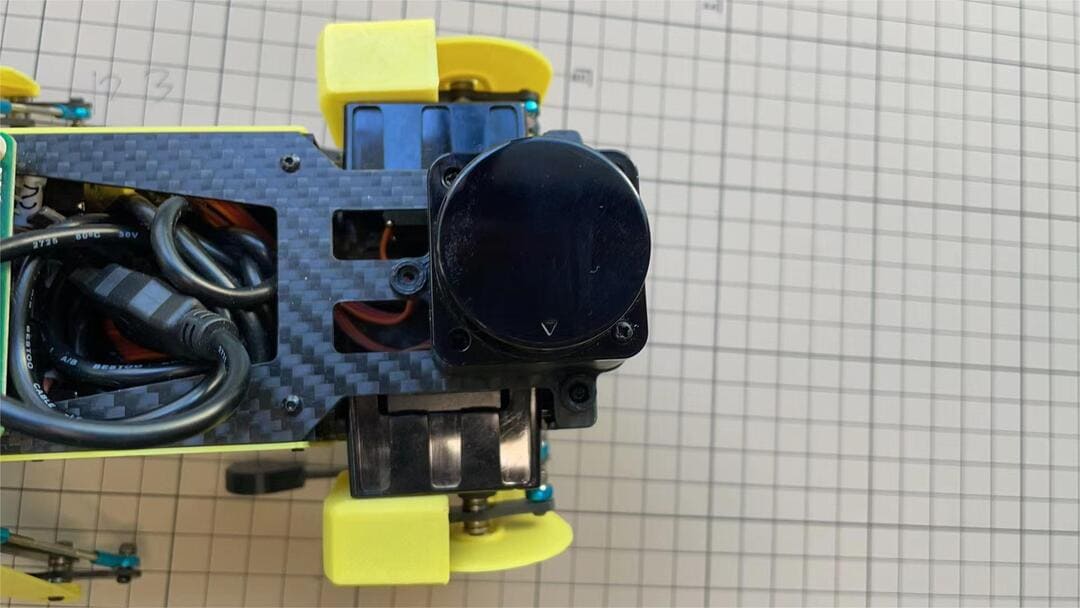

Step 5.9 Raspberry Pi 4

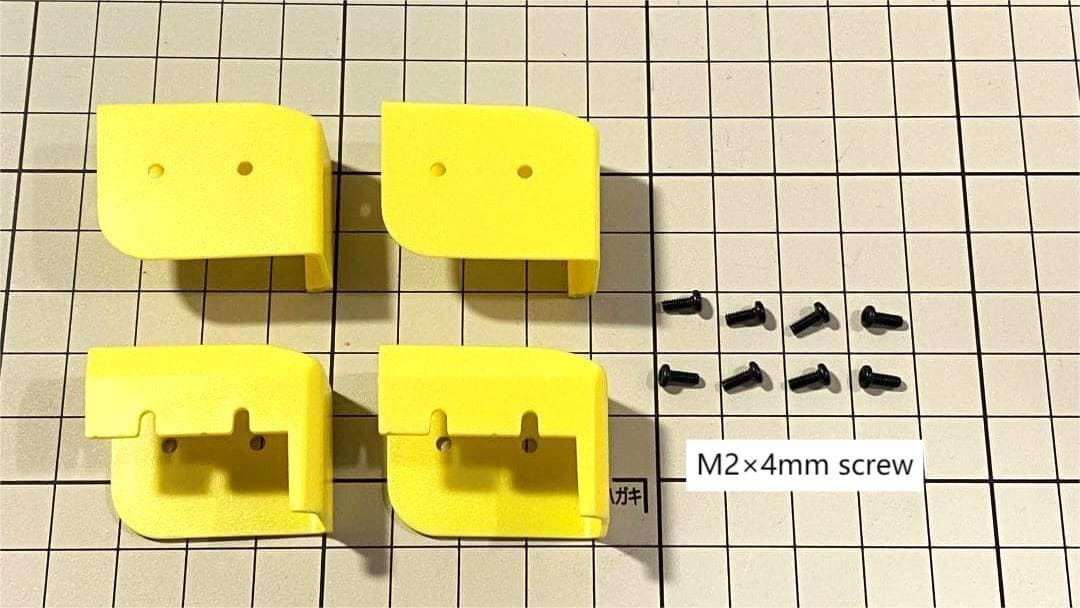

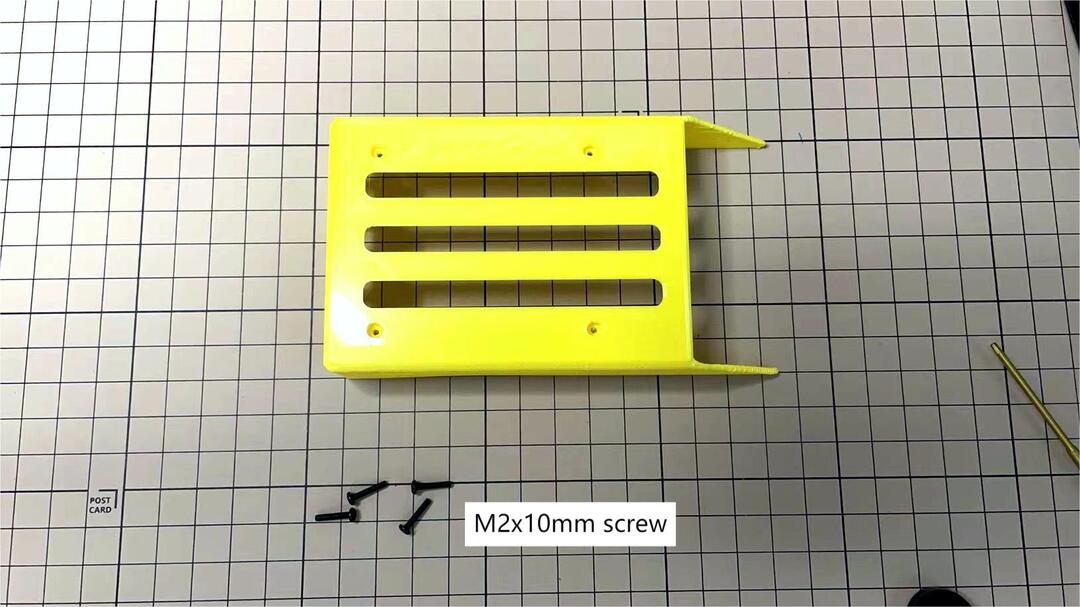

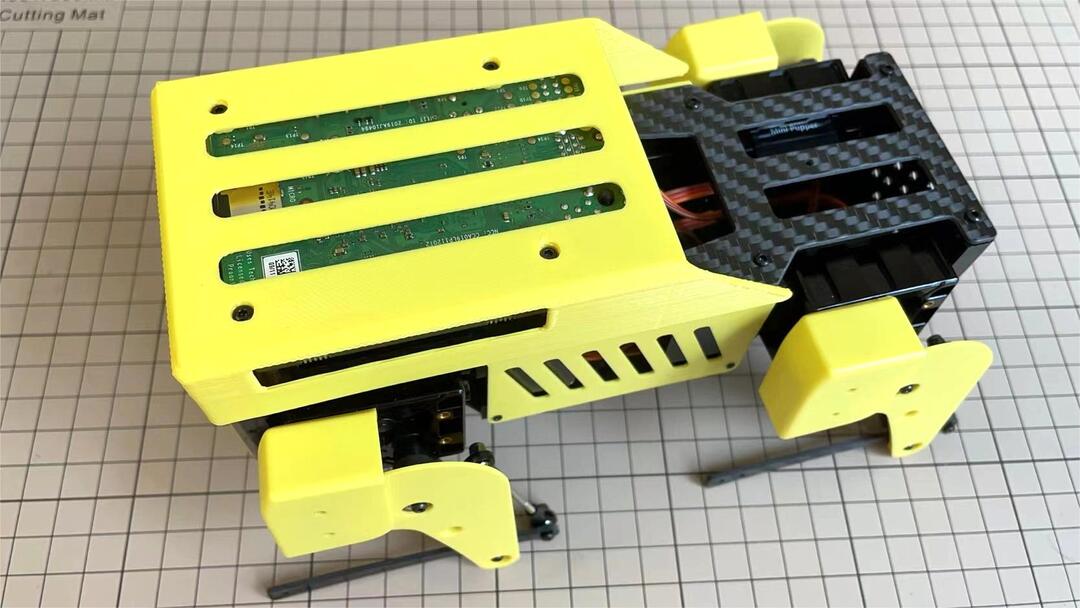

6. Cover Assembly

Please refer to the below video clip.

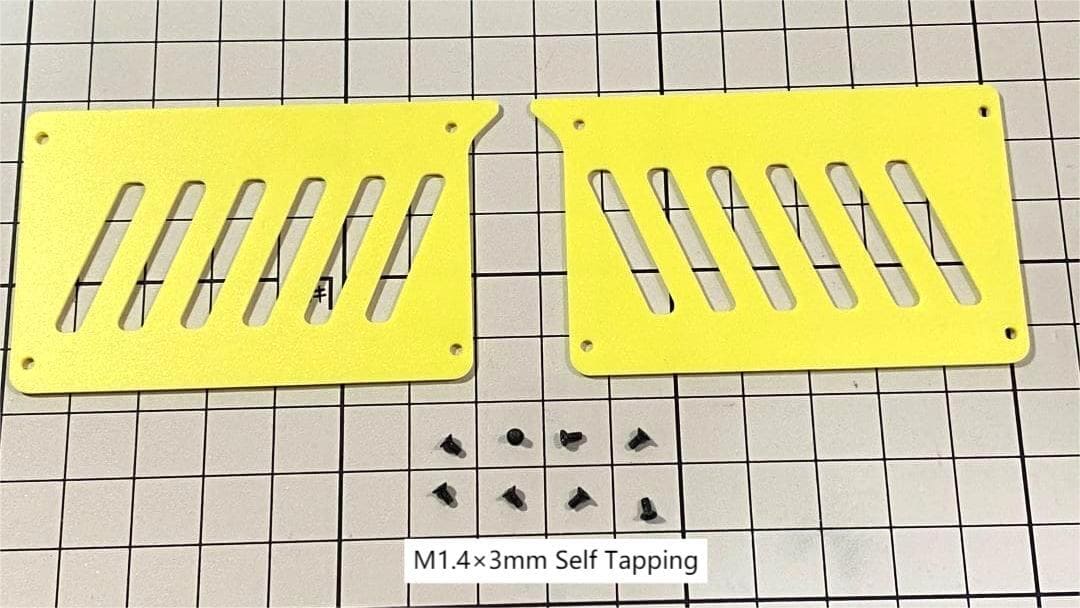

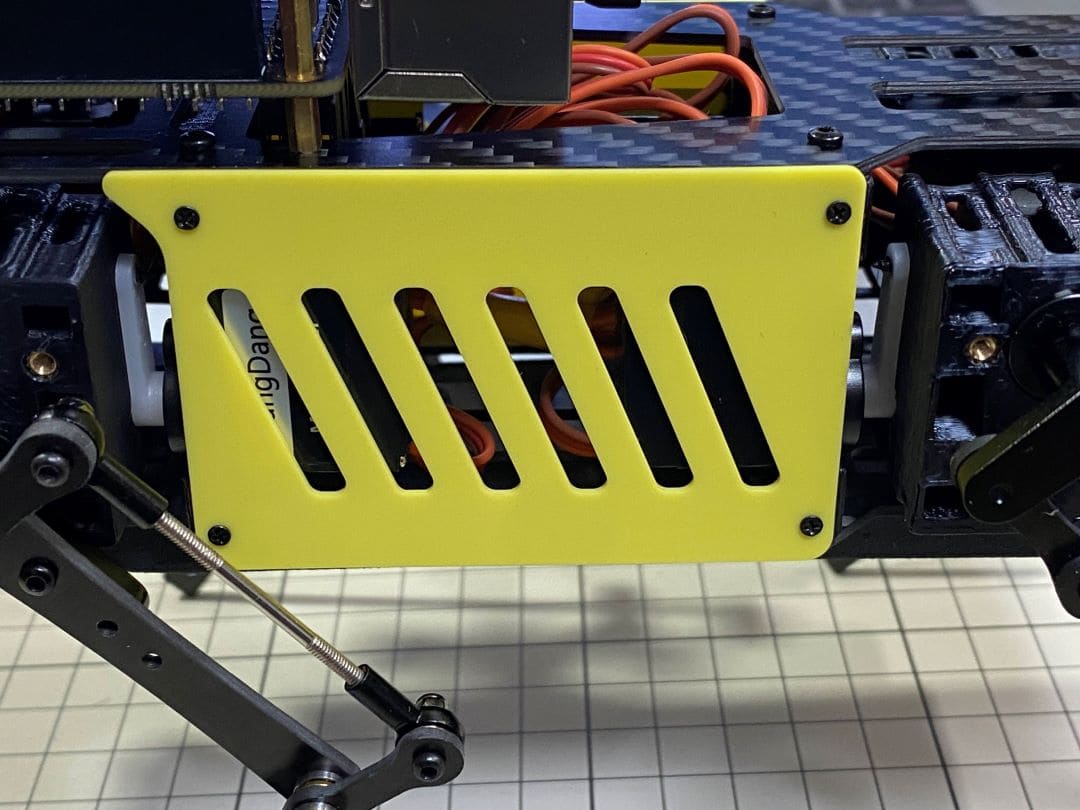

Step 6.1 Side panels

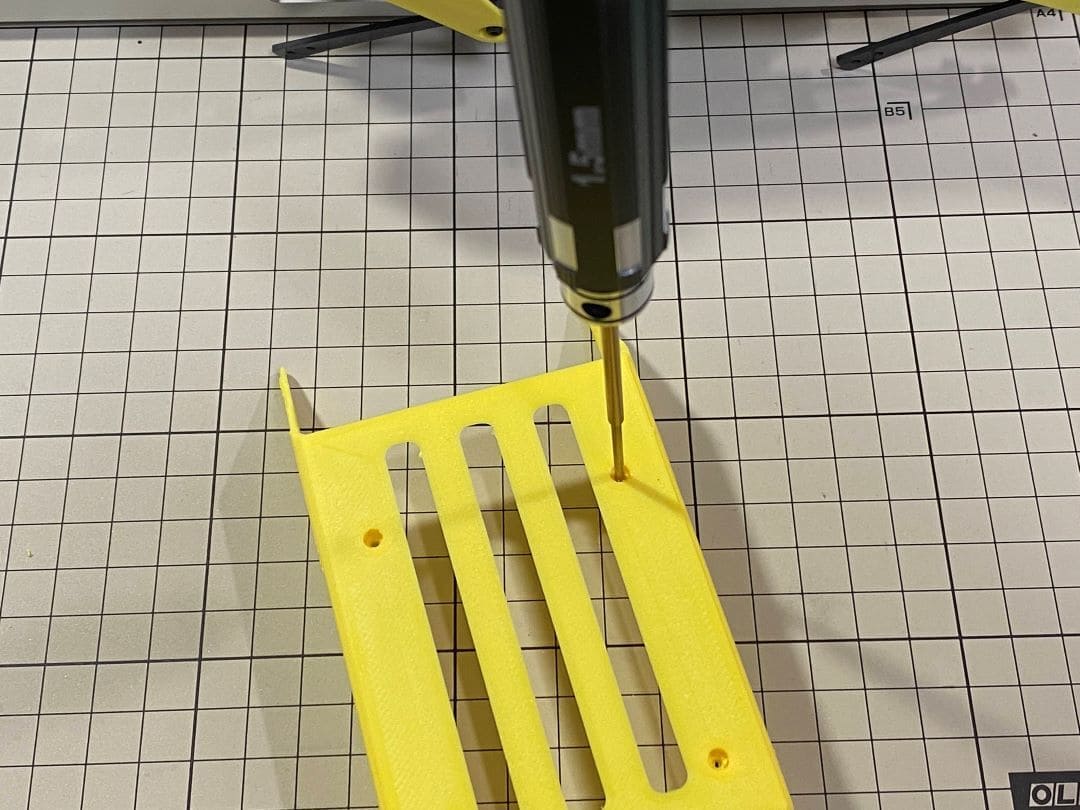

Step 6.2 Shin guards

Use four M2x10mm countersunk screws.

Step 6.3 Shoulders

Insert only the screws first and then insert the shoulder parts into the gap. Insert the 2 mm hex driver into the hole in the shoulder part and tighten the screws.

Step 6.4 Top cover

Use four M2x10mm screws, if the holes are too small to fit the screws, as the part is made with a 3D printer, you can enlarge the holes by turning them with the supplied 2mm hexagonal screwdriver.

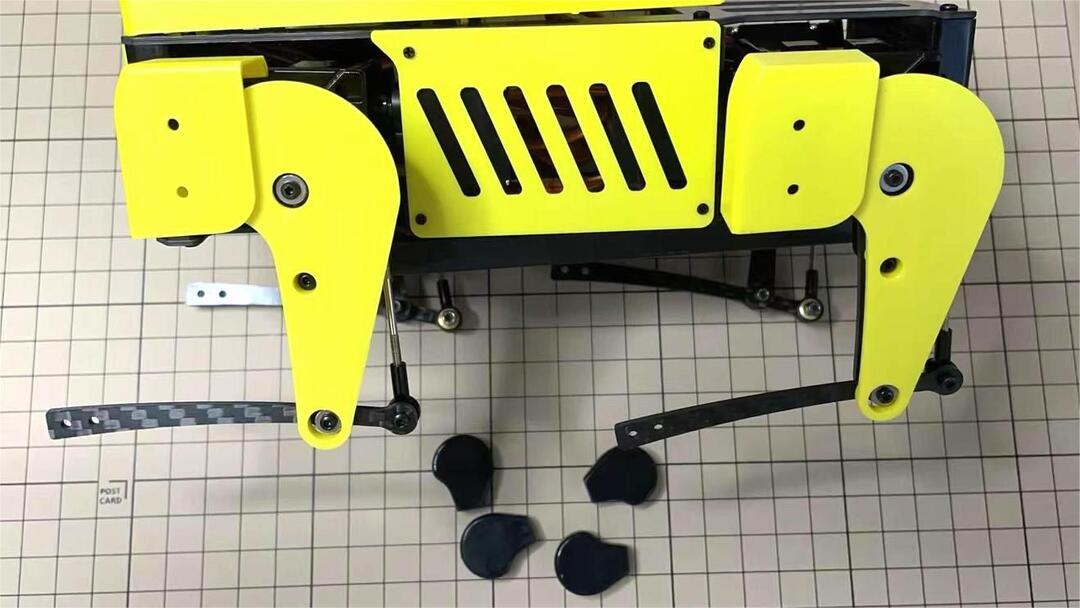

Step 6.5 Shoes

Put on 4 shoes.

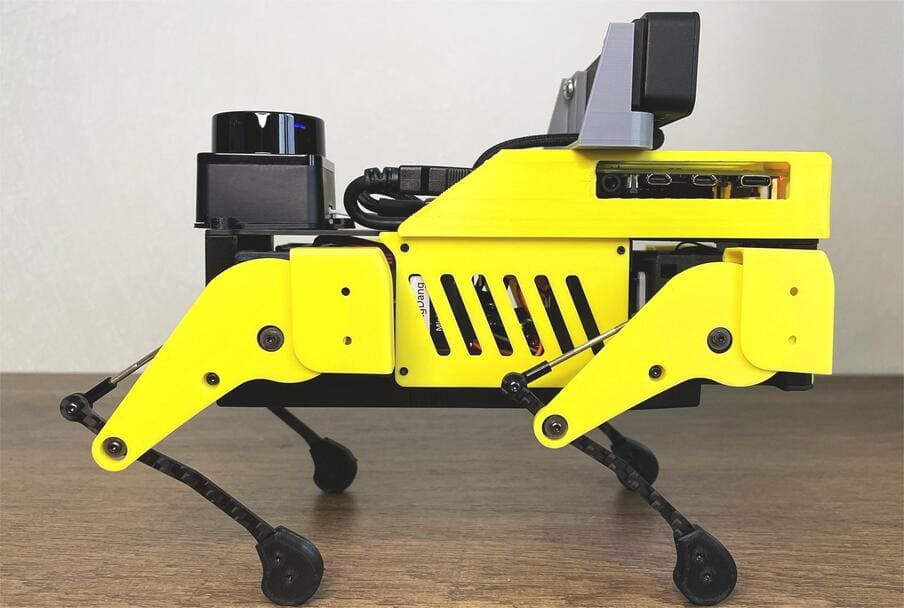

Step 6.6 Completion!

7.Add-On Assembly

Step 7.1 Lidar

If you order the Lidar, the Lidar holder will be shipped together.

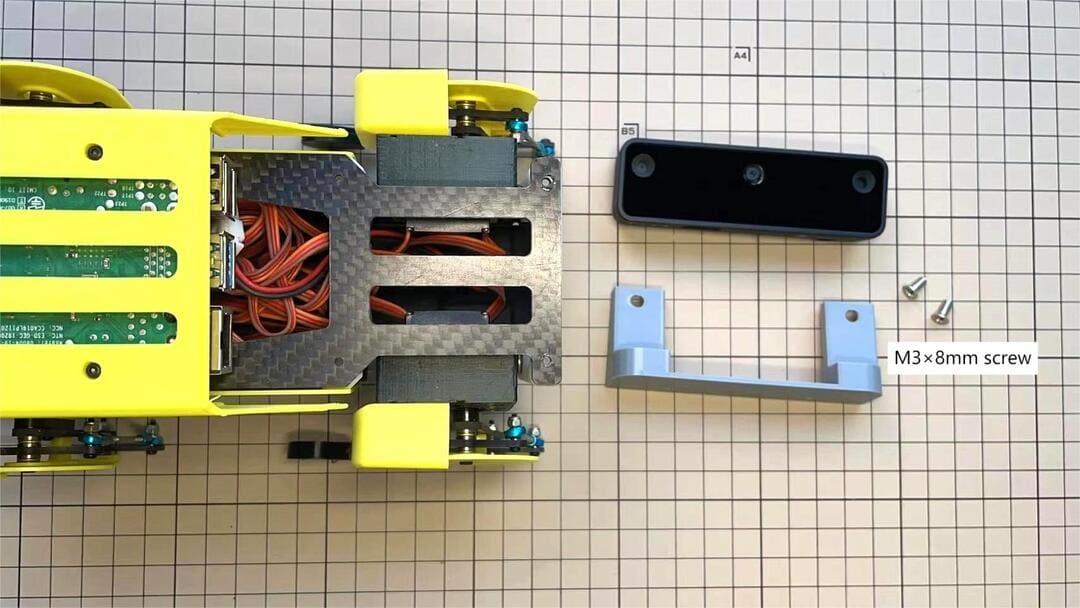

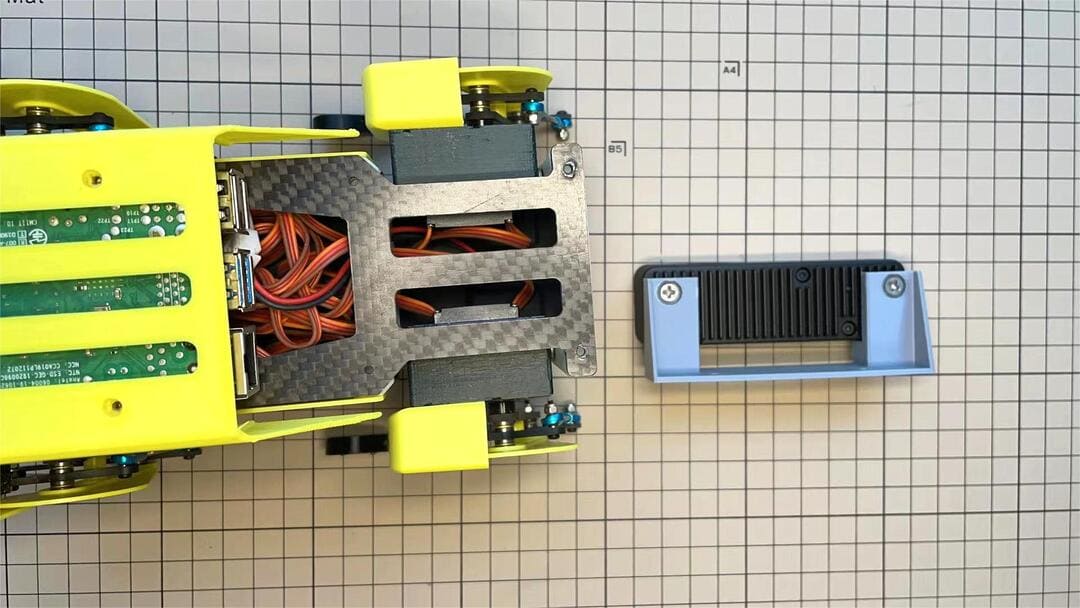

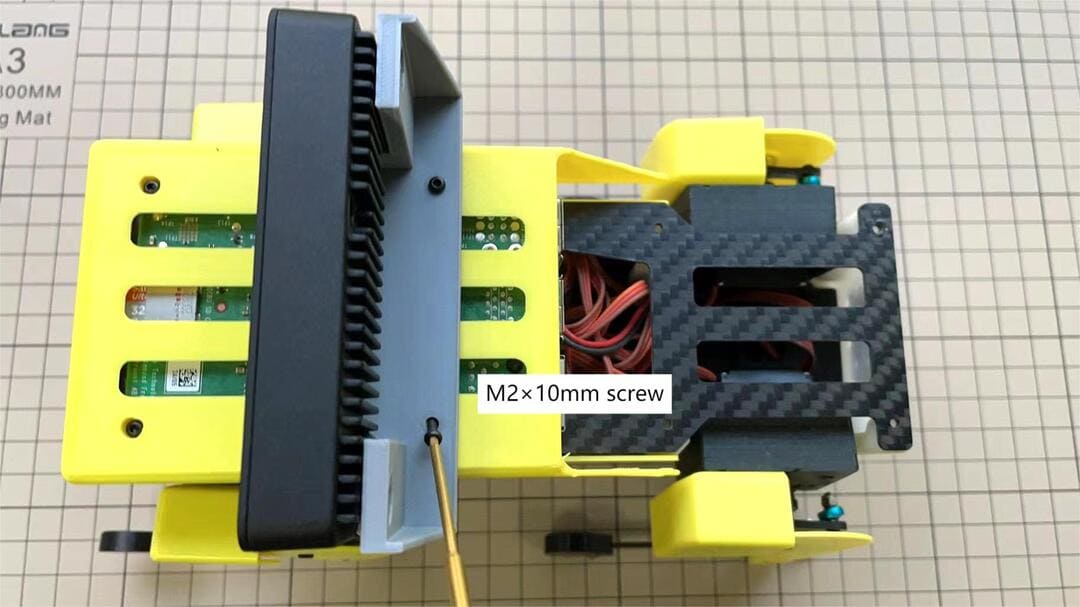

Step 7.2 Camera

If you order the camera, the camera holder is not included in the kit. But you can 3d-print it from the stl file down below.

https://drive.google.com/drive/folders/1lRADDbAt7mSBJE4j8HCji1WbWcpneUED

Step 7.3 Completion!